Forklift safety

7 ways to reduce accident risk from your forklift operations

A recent BITA analysis of RIDDOR reports has revealed that, despite being a seemingly straightforward process, one in 25 forklift-related accidents occurs when an operator is entering or exiting the truck.

As such a frequently executed manoeuvre, it’s vital that you do what you can to ensure any risk is sufficiently reduced — but how do you do it?

As such a frequently executed manoeuvre, it’s vital that you do what you can to ensure any risk is sufficiently reduced — but how do you do it?

Here, Forklift training provider Mentor, provides some tips to help you avoid some of the most common hazards, ensure safe practice and prevent costly accidents:

1. Limit risk of slips and falls when mounting/dismounting truck

Because they do it so often, lift truck operators can become complacent during mounting/dismounting, trying to shortcut the process because they don’t fully appreciate the risks involved… or the consequences.

The steps on forklifts are relatively small and, as one HSL study confirms, wear most at the spot where the operator’s boot rotates over the step’s edge. That constant use makes it particularly slippery.

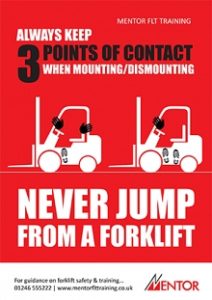

A simple rule that should form part of any basic forklift training course is maintaining three points of contact when entering or exiting a truck.

Operators should keep either one hand and two feet, or two hands and one foot, on the truck at all times, until they are either in their seat or standing firmly on the ground. This free 3 points of contact poster sums it up well as a handy reminder for operators on site.

Operators should keep either one hand and two feet, or two hands and one foot, on the truck at all times, until they are either in their seat or standing firmly on the ground. This free 3 points of contact poster sums it up well as a handy reminder for operators on site.

Best practice for mounting and dismounting a forklift truck is as follows:

• Mount/dismount only when the truck is stationary;

• Face the truck;

• Use the handgrips and steps provided;

• Look all around for hazards;

• Get on and off the truck under control and one foot at a time;

• Do not jump;

• Take extra care in rain, snow, or icy conditions.

2. No jumping down to dismount

As we’ve seen, dismounting incorrectly can increase the risk of a slip or fall, but the consequences can be more serious when operators jump down from their cab.

Operators may be tempted to make a quick exit but jumping puts them at a greater distance from the truck — and potentially into the path of another vehicle. By maintaining three points of contact, and facing towards the vehicle as they dismount, they can pull themselves back into the cab and out of danger. Jumping also puts stress on the knees and back which can affect mobility, or it can lead to broken bones if the operator falls.

3. Don’t try to steady a load

It’s not just vehicles that can pose a risk, shifting loads are a significant hazard. Sadly, many injuries occur when someone in the vicinity tries to manually steady an unstable load.

Operators exiting their truck to steady either their own or another load are in danger of serious harm, from pinch/crush injuries when putting their hands into a moving operation, to far worse consequences should the load become unstable and fall.

If a load becomes unstable or needs to be adjusted in transit:

- Place it on the ground;

- Withdraw the forks;

- Make sure the truck is stable and turn off the ignition;

- Dismount the truck and carry out any adjustments to the load.

If the unstable load is in the racking, the area should be cordoned off and the Manager or Supervisor informed immediately so that the risk can be dealt with before it can cause harm to someone in the vicinity.

4. Operate from inside the cab only

Most modern lift trucks are now fitted with a weight-operated micro-switch, which is activated by an operator sitting on the seat to allow the controls to function. However, when this isn’t the case, operators may be tempted to access the controls from outside the truck.

Doing so immediately puts the operator, and those working around them, in a position of danger. To reduce the risk:

- Never operate the controls from anywhere but seated inside the FOPs of the cab;

- Do not stand next to the operating mast where you could be hit by the load;

- Never work with an obstructed view — sit in the cab for the clearest viewpoint;

- Do not allow the vehicle to move without the operator inside as it can run them (or someone else) over.

5. Stay within the confines of the truck

Staying inside the truck during operations dramatically reduces the risk of an accident for your operators. But don’t forget, that danger immediately returns if they allow any part of their body to stray outside the confines of the cab.

Staying inside the truck during operations dramatically reduces the risk of an accident for your operators. But don’t forget, that danger immediately returns if they allow any part of their body to stray outside the confines of the cab.

Operators should never lean or reach outside of the cab, as this puts them at risk of contact with passing obstructions/vehicles. Rather than reach out to access something, they should stop their truck in a suitable place, make it safe, dismount, and then access it on foot. If the load is obstructing the operator’s view, and they need to lean out of the cab to see in front of them, they should be driving in reverse, giving themselves a clear view of their route and any upcoming hazards.

6. Take extra care around truck controls

The most common cause of unintentional operation is when the operator exits the truck on the wrong side and accidentally leans on the controls. What’s more, some functions such as mast tilt, fork lowering or reach extension are gravity fed, which means they can be accidentally operated even when the power is switched off. Ensuring that operators exit on the correct side of the truck will reduce the risk of this happening. This side will be fitted with appropriate handles to aid them.

7. Monitor your operations

All these fundamental safety principles should be covered during your operators’ basic forklift training course. However, as with your site rules or procedures, they’re only effective if they are constantly enforced.

To successfully implement best practice, it’s your role to make sure your staff are motivated, trained and receive regular monitoring by managers and supervisors to ensure safe operation sticks, for the long term.

7 ways to reduce accident risk from your forklift operations

One in 25 forklift-related accidents occurs when an operator is entering or exiting the truck. Here are 7 ways to help reduce forklift accidents.

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Company fined after worker spotted on pallet raised by forklift truck

Barcode Warehouse fined £500k after forklift truck death

Creating safer forklift truck operations

As such a frequently executed manoeuvre, it’s vital that you do what you can to ensure any risk is sufficiently reduced — but how do you do it?

As such a frequently executed manoeuvre, it’s vital that you do what you can to ensure any risk is sufficiently reduced — but how do you do it? Operators should keep either one hand and two feet, or two hands and one foot, on the truck at all times, until they are either in their seat or standing firmly on the ground.

Operators should keep either one hand and two feet, or two hands and one foot, on the truck at all times, until they are either in their seat or standing firmly on the ground.  Staying inside the truck during operations dramatically reduces the risk of an accident for your operators. But don’t forget, that danger immediately returns if they allow any part of their body to stray outside the confines of the cab.

Staying inside the truck during operations dramatically reduces the risk of an accident for your operators. But don’t forget, that danger immediately returns if they allow any part of their body to stray outside the confines of the cab.

No mention of seat belt wearing. We regularly see reports of forklift overturning incidents where the operator is fatally injured due to not wearing a seat belt.

This article is really helpful for forklift operators. Thank you for sharing your knowledge about this topic.