PPE is the personal protective equipment that will protect the user against health or safety risks.

This guide includes an explanation of the PPE 2018 regulations, best practice advice for health and safety professionals and useful resources for further reading.

On 6 April 2022 the regulations on wearing PPE at work changed. The updated Regulations apply to all employers in Great Britain in a wide range of sectors and industries.

Click here to read more about new PPE at work regulations.

What is PPE?

PPE can include items such as safety helmets, gloves, eye protection, hazmat suits, high-visibility clothing, safety footwear, safety harnesses, ear plugs, ear defenders and respiratory protective equipment (RPE). In appropriate situations disposable PPE may be provided; eg single-use coveralls. Employers have duties concerning the provision and use of personal protective equipment at work.

PPE does not include:

- Ordinary working clothes or uniforms not designed to provide for the health or safety of workers;

- Clothing provided for food hygiene purposes;

- Equipment used for protection while travelling on a public road (ie motorcycle or bicycle helmets);

- Equipment used during competitive sport competitions (but other protective equipment used by sports instructors would be included eg life jacket worn by canoe instructor);

- An offensive weapon used as self-defence or as deterrent equipment. For example, truncheons or CS gas canisters as used by the police or military (but helmets, body armour and other PPE used to protect staff from physical violence, is included);

- Portable devices for detecting and signalling risks and nuisances, such as badges for detecting radiation, or personal gas detectors.

Health and safety visitors to Crossrail dressed in PPE

Why is PPE important?

In the hierarchy of risk control, PPE is considered to rank lowest and represent the option of last resort. It is only appropriate where the hazard in question cannot be totally removed or controlled in such a way that harm is unlikely (for example by isolating the hazard or reducing the risk at source to an acceptable level).

There are a number of reasons for this approach:

- PPE protects only the person using it, whereas measures controlling the risk at source can protect everyone at the workplace;

- Theoretical maximum levels of protection are seldom achieved using PPE, and the real level of protection is difficult to assess (due to factors such as poor fit, or failure to wear it when required). Effective protection can only be achieved by equipment which is correctly fitted, maintained and properly used at all times;

- PPE may restrict the wearer by limiting mobility, visibility or by requiring additional weight to be carried.

- Use of PPE may alter employees’ perception of the hazards they are dealing with.

In this context of a last resort control measure, PPE is critically important as it is generally only used where other measures are insufficient and as such it plays a crucial role in preventing and reducing many occupational fatalities, injuries and diseases.

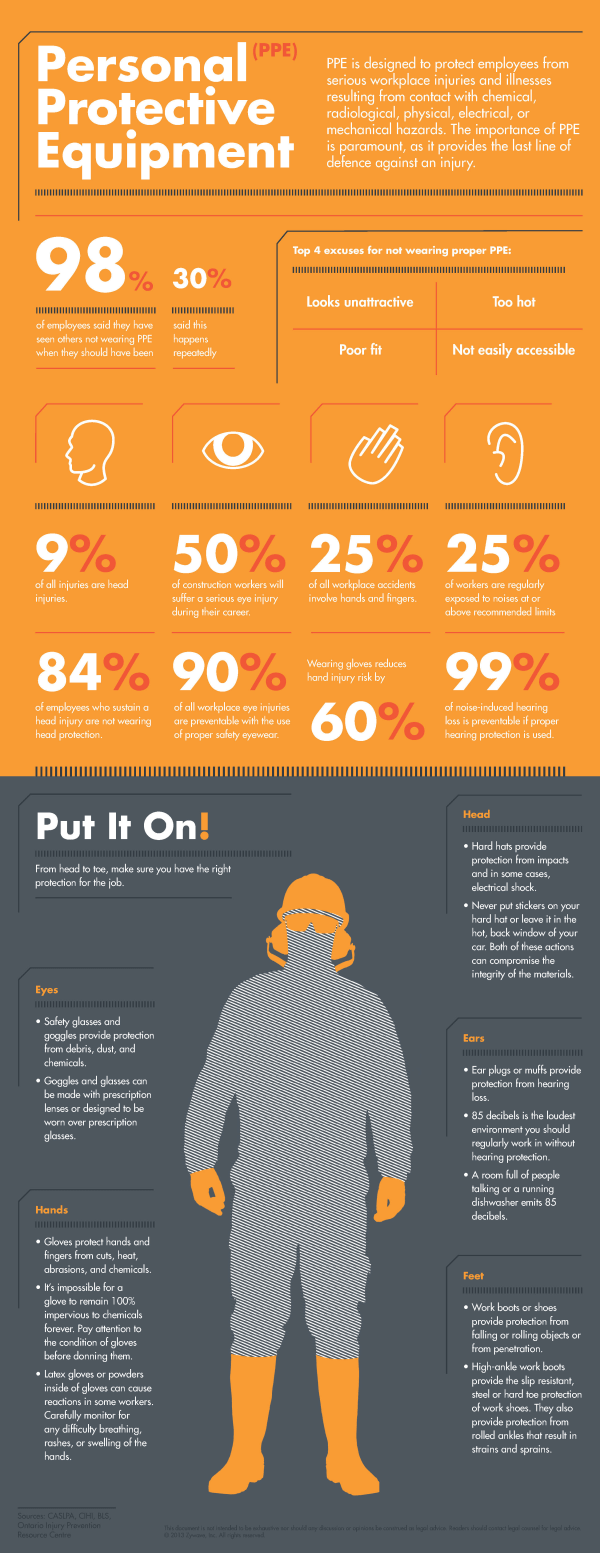

PPE in numbers

This infographic provides some key facts and figures:

PPE at work regulations to be updated

From 6 April 2022 the regulations on wearing PPE at work have changed. Here, we explain what’s changing for who, and why.

The updated Regulations apply to all employers in Great Britain in a wide range of sectors and industries.

Workers are required to use the PPE properly following training and instruction from their employer.

Personal protective equipment (PPE) guidance

PPE is equipment that protects users against health or safety risks at work. It can include items such as safety helmets, gloves, eye protection, high-visibility clothing, safety footwear and safety harnesses. It also includes respiratory protective equipment (RPE).

Personal protective equipment (PPE) at work regulations from 6 April 2022

Here, HSE explains changes to the scope of the PPE Regulations which apply from 6 April 2022, when the Personal Protective Equipment at Work (Amendment) Regulations 2022 (PPER 2022) came into force and amend the 1992 Regulations (PPER 1992).

They extend employers’ and employees’ duties regarding personal protective equipment (PPE) to limb (b) workers.

This document outlines the following key information, explaining what has changed and what this means for both employers and workers:

- duties unchanged but extended

- definitions of limb (a) and limb (b) workers

- what PPE is

- hierarchy of controls

- employers with both employees and limb (b) workers

- employers with only limb (b) workers

- how this legislation will be enforced

- PPE not regulated and enforced under PPER 1992.

Risk at Work – Personal protective equipment (PPE)

Employers responsibilities to workers on providing PPE changed on 6 April 2022. The Personal Protective Equipment at Work Regulations 2022 amend the 1992 Regulations to extend employers’ and employees’ duties in respect of PPE to a wider group of workers.

HSE – L25 – Personal protective equipment at work – revised edition

Employers’ responsibilities to workers on providing PPE changed on 6 April 2022. This guidance explains how you can comply with the Personal Protective Equipment at Work Regulations 1992 (PPER 1992) as amended by the Personal Protective Equipment at Work (Amendment) Regulations 2022 (PPER 2022).

Under PPER 2022, employers’ and employees’ duties and responsibilities under PPER 1992 are unchanged but will extend to limb (b) workers, as defined in PPER 2022.

If PPE is required, employers must ensure their workers (including limb (b) workers) have sufficient information, instruction, and training on the use of PPE.

This document explains these changes, and the new responsibilities employers and employees must consider.

Click here for more on L25 – Personal protective equipment at work

Personal Protective Equipment and coronavirus

WHO releases technical specifications of PPE for COVID-19

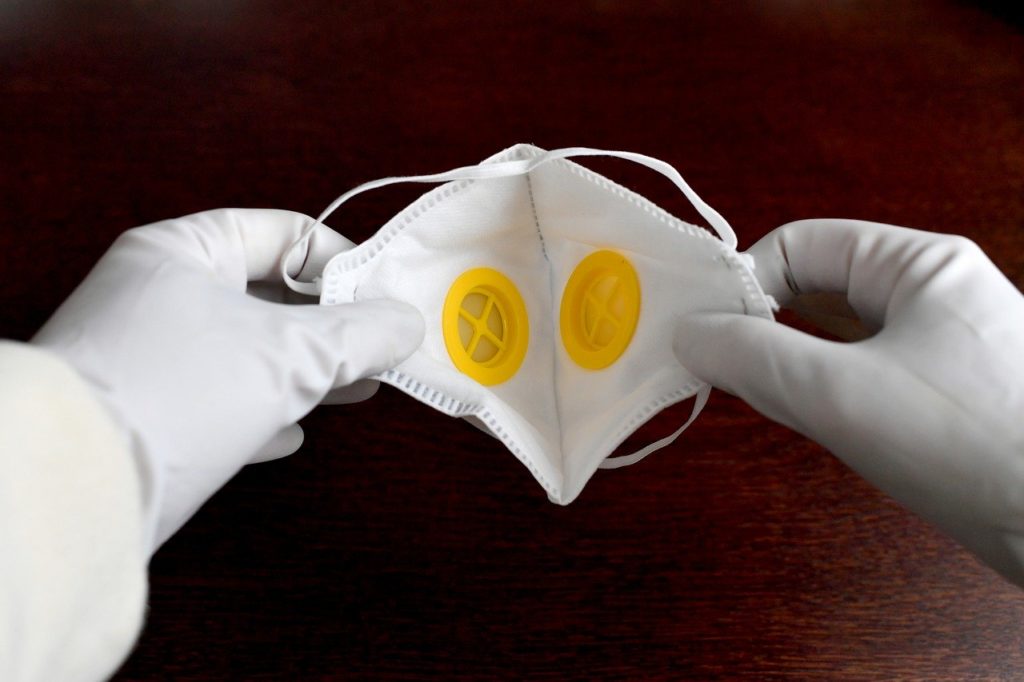

This document provides interim guidance on the quality, performance characteristics and related standards of personal protective equipment to be used in the context of COVID-19. This includes WHO Priority Medical Devices, specifically: surgical masks, non-surgical masks, gloves, googles, face shields, gowns and N95 masks. It is intended for procurement agencies, occupational health departments, infection prevention and control departments or focal points, health facility administrators, biomedical and materials engineering, PPE manufacturers and public health authorities at both national and facility levels.

Each PPE item listed is considered a priority medical device for COVID-19. The technical specifications define the minimum requirements for the product to ensure good quality, safety and efficacy. The methods used to develop the technical specifications involved review of the infection prevention and control (IPC) COVID-19 guidelines, review of PPE products available in the market, and PPE products approved by stringent regulatory agencies, and analysis of international, regional and country standards on PPE. The four COVID-19 guidelines analysed were:

- Rational use of personal protective equipment for coronavirus disease (COVID-19) and considerations during severe shortage;

- Advice on the use of masks in the context of COVID-19 – in the community, during home care, and in health care settings;

- COVID-19 advice for the public: when and how to use masks;

- Analysis of the PPE required to perform the clinical management of COVID-19 patients (5), and the Disease commodity package for novel coronavirus.

Sourcing PPE during COVID-19

Listen back to our on-demand webinar, part of Safety & Health Expo Digital Week, featuring Adam Young, Marketing Director, Arco, Matthew Judson, Director, Respiratory & Technical Support and Nathan Shipley, PPE Group Certification Manager, BSI.

Stories have been circulating in the media of suppliers overcharging and sub-standard products being touted as high-quality equipment. In this panel debate, PPE manufacturers and distributors will advise practitioners how they can avoid falling into these traps and what they should be wary of. The panel will also discuss some of the work they have been doing during the pandemic and how COVID-19 has affected the supply chain.

Click to listen to our Sourcing PPE during COVID-19 webinar.

Considerations for acute PPE shortages

A Public Health England document notes that where there are acute shortages of PPE, and where it is safe to do so, the HSE approves the sessional and reuse of PPE. It has agreed that the use as outlined in this document is appropriate within health and safety legislation and provides appropriate protection for health and care workers.

These are exceptional circumstances and do not reflect HSE’s standard approach. HSE expects Trusts to have an agreed action plan to support implementation which includes a consideration of all measures to manage usage effectively.

UK Government: Coronavirus (COVID-19): personal protective equipment (PPE) hub.

Everything that you need to know on the supply and use of Personal Protective Equipment.

Statement from HSE regarding PPE and the asbestos industry

The Asbestos Removal Contractors Association (ARCA) has reported that the HSE has received a number of queries concerning the purchase and use of Type 5 coveralls. It has issued a statement as a reminder of existing guidance and advice. When buying Type 5 coveralls, especially from new sources of supply, you should check they are CE marked and provided with a Declaration of Conformity with accompanying instructions in English. The relevant standard for Type 5 Cat III coveralls is BS EN ISO 13982-1:2004+A1:2010, which will be specified on the Declaration of Conformity.

Read the HSE Statement in full, here.

Technical Specifications for PPE

The Cabinet Office and Department of Health and Social Care have issued guidance in order for new suppliers and manufacturers to understand government requirements.

There are two documents:

- Specification for Examination Gloves;

- Specification for Gowns Surgical Face mask, Respirator masks and Eye Protection (PPE).

The specifications reference a number of standards and legislation. The list of standards/legislation/directives is not intended to be exhaustive and any relevant standard/legislation/directive (even if not stated) must be complied with.

It is stressed that products must comply with the stated standards/legislation/directives (as amended, extended or re-enacted from time to time) and/or the relevant section within the standard/legislation/directive and/or the relevant standard within the stated suite of standards.

Evidence of compliance to the standards/legislation/directives must be available to NHS Supply Chain on request during the lifetime of the Agreement; without it, NHS Supply Chain can suspend the product.

Putting on respirators and fit checking: HSE releases advice for healthcare workers during the #coronavirus outbreak.

Face fit testing: The essentials

Visit the SHP Coronavirus advice for employers hub page.

PPE legislation

The Health and Safety at Work, etc Act 1974 places a general duty of care on employers for ensuring the safety of their employees and others and requires that no charge may be made for anything done for the purposes of compliance (eg providing PPE) (Section 9). Furthermore, the Management of Health and Safety at Work Regulations 1999 require employers and self-employed people to carry out a suitable and sufficient risk assessment for all work activities for the purpose of deciding what measures are necessary for safety.

Those responsible for carrying out a risk assessments are required to identify precautions and measures that protect people from harm. The provision of PPE is a legitimate response to the presence of hazards in the workplace, but should only be applied where other measures to remove, reduce or isolate the hazard are likely to prove insufficient. Regulation 4 of the Personal Protective Equipment at Work Regulations 1992 (the Regulations) makes it clear that employers must provide suitable PPE for employees exposed to health and safety risks except ‘where and to the extent that such risk has been adequately controlled by other means which are equally or more effective’. A similar duty applies to the self-employed with regard to supplying PPE for their own use.

PPE regulations 2018

European health and safety legislation on PPE changed in 2018. The new Regulation, which replaced the 25-year-old Directive, reflects modern ways of bringing PPE to the market as well as changes in technology and production techniques.

The draft text for the new Regulation (EU) 2016/425 was approved by the EU and became official on publication in the OJ (the Official journal of the European Union) on 31 March 2016. The Regulation became law on 21 April, leading directly to all member states having to adopt the legislation.

Full enforcement took place in April 2018, repealing the old PPE Directive 89/686/EEC after a two-year transition period. From that date, all personal protective equipment had to be certified to the new Regulation.

The Regulation directly affects importers, distributors and retailers, who now have to share responsibility for providing safe and effective products with manufacturers. Anyone in the PPE industry is now legally required to comply with the Regulation.

The rebranding of the PPE Directive as a Regulation was a significant alteration. A ‘Regulation’ is a binding legislative act. It must be applied in its entirety across the EU, whereas a ‘Directive’ is a legislative act that sets out a goal that all EU countries must achieve. In the past it was up to individual countries to decide how they did this.

Making the legislation international, and thus ensuring all Europeans get safer PPE, is the chief reason the EU has made this change from a Directive to a Regulation.

In an interview, Neil Hewitt, Divisional Director of Quality and Technical Standards at Arco, told SHP that ‘The new PPE Regulation (EU) 2016/425 brings about the most significant changes to the rules surrounding PPE, since the introduction of the first Directive over 20 years ago’. Read the full interview here.

PPE at work regulations to be updated

Key changes

All organisations involved with the production, importation, supply, distribution, marketing and sale of PPE will have the same responsibilities as the manufacturer, including getting product approval, making sure it conforms to the Regulation and keeping technical files and records. This will level the playing field between manufacturers and importers, and mean that fewer low-specification and counterfeit products will get into the EU marketplace.

- Change of categorisation from product related to risk related;

- Change of classification for certain product categories; Hearing Protection, now categorized as ‘harmful noise’ (risk) is moving from category II to III.

- EC Declaration of Conformity to be provided (or with a web link) with each product.

- 5-year validity / expiry date for new EU Certificates.

- Increased obligations on ‘economic operators’ – being the total supply chain, including manufacturers, importers and distributors.

PPE will not satisfy the requirement that it is ‘suitable’ unless:

- It is appropriate for the risks and the conditions at the place of work;

- It takes account of ergonomic requirements and the state of health of the person who may wear it;

- It is capable of fitting the wearer correctly (if necessary after adjustments within the design range);

- So far as is reasonably practicable, it is effective to prevent or adequately control the risk, without increasing overall risk;

- It complies with community directives applicable to the item (i.e. CE marked).

The Regulations also require that:

- Where more than one item of PPE is to be worn, that the items are compatible;

- PPE is properly assessed before use to ensure it is suitable – to assess the risks which the PPE is to control, to evaluate the characteristics required of the PPE in order for it to be effective against the risks, and to check that the PPE selected has those characteristics;

- PPE is maintained in an efficient state, in efficient working order and in good repair (including replacement and cleaning as appropriate).

- Appropriate accommodation is provided to store the PPE when it is not being used;

- Employees are provided with instructions on the risks which the PPE will avoid or limit, the reason for using the PPE, how to use it safely and effectively, actions needed by the employee to keep it in good order eg cleaning, replacement, storage (such instruction must be comprehensible to the persons to whom it is provided);

- Employers take reasonable steps to ensure the PPE is used correctly by employees.

Employees themselves also have duties to use the PPE in accordance with their training, report loss or defect and to store the PPE as instructed. The self-employed similarly have a duty to make full and proper use of PPE.

The Regulations do not apply where there is other legislation with mandatory requirements for the provision and use of PPE in relation to specific hazards:

- The Control of Lead at Work Regulations 2002 (as amended).

- The Ionising Radiations Regulations 1999 (as amended).

- The Control of Asbestos Regulations 2012.

- The Control of Substances Hazardous to Health Regulations 2002 (as amended)- The Control of Noise at Work Regulations 2005 (as amended).

Duties – Employers

Employers should provide PPE to their employees only where there is a health and safety risk that cannot be adequately controlled by other means.

Where risks cannot be controlled by other means then PPE must be provided. It must:

- Be appropriate for the risks and for the working Environment;

- Take account of the user’s health, ergonomics, fit factors and be compatible with other items of PPE required to be worn;

- Adequately control the risk presented by the hazard without increasing overall risk experienced by the worker. For example, goggles which are to be used in a hot environment and therefore steam up making it difficult to see;

- Be supplied free of charge if supplied for work-related health-and-safety reasons;

- Be properly maintained and suitably stored (in practice, for mobile workers, it may be necessary to supply a holdall or other container to prevent damage to PPE in transit);

- Comply with relevant legislation implementing the European Directives concerning the design and manufacture.

Employers are also recommended to consult the potential wearers of PPE before items are supplied because they are usually best placed to know what is demanded by their jobs and the type and configuration of PPE that is best suited to their working environment.

It is also recommended, that employers maintain a record of the items issued, to whom, the date of issue and the date of any replacement or maintenance required.

Furthermore, there are also considerable differences in physical dimensions of different workers, depending on their gender, ethnicity, and lifestyle, therefore, different sizes and contours should be available to fit wearers. PPE should also be adjustable and where problems occur, advice should be sought to take account of any medical conditions. In the case of close fitting respiratory protection specific employee fit testing is required. Training, instruction and information will also need to be provided to wearers of PPE. In providing this the following details should be included of:

- The risks the PPE will avoid or limit;

- The purpose and manner in which the PPE is to be used;

- Action to be taken by the employee to ensure good working order, as well as hygienic condition.

Any training provided should be comprehensible to those receiving it (literacy and language barriers should be taken into account), and should cover the theory and practice of using PPE with a view to ensuring that users understand not only how to use the PPE, but also why it is important that they do so. Employers should also organise demonstrations of the use of PPE, with regular refresher training. Clearly, the extent of this instruction will depend on the item. In the case of a high visibility vest simple reinforcement of the requirement to wear it in certain work areas should be sufficient, in the case of a complex item such as a lifejacket or harness, much more detailed instruction is required. Each type of PPE is required to be manufactured to relevant harmonised European standards (CEN standards).

Where PPE is supplied for the first time, it must conform to the appropriate European or British Standard. It is unlawful for suppliers to provide PPE which does not carry the ‘CE’ mark. PPE must be maintained in efficient working order and in good repair in accordance with manufacturers’ maintenance schedules and instructions. An effective system of monitoring and maintenance or replacement should be set-up. This will include appropriate periodic checks along with records of tests and examinations.

A stock of proper CE-marked spare parts should be available to replace damaged or defective elements of the PPE with any repairs carried out by only those competent to undertake them. PPE awaiting repair should be stored separately and be clearly identifiable from PPE that is ready-to-wear.

There should also be a system by which employees can report missing or lost items of PPE and arrange for them to be replaced.

Heat Resistant Safety Gloves

Duties – Employees

With regard to PPE employees are required to correctly use any such items provided as directed and in accordance with any training, instructions or information they have received.

Aside from proper use, employees are also required to return PPE to its storage place after use unless agreed

otherwise with the employer. Employees must take care of PPE and report defects or loss of equipment as soon as they become aware of them.

Charging

Employers cannot charge an employee for providing or replacing PPE, regardless of whether the PPE in question is returnable or not. This prohibition on charging extends to agency workers if they are legally regarded as employees. If employment has been terminated and the employee keeps the PPE without the employer’s permission, then, as long as it has been made clear in the contract of employment, the employer may be able to deduct the cost of the replacement from any wages owed or require the return of the equipment.

Assessing suitable PPE

The type and nature of the hazards in the workplace will be a primary indicator of the right type of PPE. The following questions should be considered when assessing whether PPE is suitable or not:

- Is it appropriate for the risks involved and the conditions at the place where exposure to the risk may occur? For example, eye protection designed for providing protection against agricultural pesticides will not offer adequate face protection for someone using an angle grinder to cut steel or stone;

- Does it prevent or adequately control the risks involved without increasing the overall level of risk?

- Can it be adjusted to fit the wearer correctly? (In the case of close fitting respiratory protective equipment specialist fit testing is required);

- Has the state of health or needs of those who will be wearing it been taken into account?

- What are the needs of the job and the demands it places on the wearer? For example, the length of time the PPE needs to be worn, the physical effort required to do the job and the requirements for visibility and communication;

- If more than one item of PPE is being worn, are they compatible? For example, does a particular type of respirator make it difficult to get eye protection to fit properly?

Further advice may be sought from suppliers of PPE, or in particularly difficult cases from specialist sources or from the PPE manufacturer. Another useful source of information is the British Safety Industry Federation.

Types of PPE

Various types of PPE are available for use in the workplace. The Health and Safety Executive provides guidance and general information about types of PPE used in industry, but it doesn’t cover specialised and less-used items.

Detailed information should be obtained from suppliers on these more specialised items. Potential users should be involved in the selection of equipment they will be expected to wear and if possible more than one model should be made available to them.

The different types of PPE include:

- Head and scalp protection;

- Respiratory protection;

- Eye protection;

- Hearing protection;

- Hand and arm protection;

- Foot and leg protection;

- Body protection;

- Height and access protection.

Head and scalp protection

There are five primary purposes of head protection, to protect:

- The head in falls;

- Against falling objects, impact with fixed objects, or wielded weapons;

- The head by offering thermal insulation;

- Against entanglement and laceration to the head;

- Against scalping/entanglement particularly on machinery where injuries are still numerous. Hair-nets and caps are also used for hygiene reasons.

All forms of head and scalp protection must be suitable, correctly fitted and have an easily adjustable headband, nape and chin strap where appropriate. The relevant standards are BS EN 397 and BS EN 14052.

Eye protection

PPE for the eyes is intended to provide protection against impact, cuts, splashes, mists and sprays. The relevant standards are BS 7028 (Guide to Selection of Eye Protection for Industrial and Other Uses) and BS EN 166 (Specification for Eye Protectors).

All PPE must be regularly cleaned, but this is especially important in the case of eye protection as dirty lenses lead to poor vision and may contribute to accidents.

Where lenses become scratched, pitted or cracked they should be replaced.

Users who need to wear corrective lenses (glasses) should have this requirement accommodated in the provision of the PPE to them eg as protective over glasses where appropriate, or in the form of prescription lenses if necessary. Where they may be required to wear eye protection on a regular and prolonged basis then any goggles, safety-glasses etc should meet the user’s prescription requirements.

Hearing protection

Assessments carried out under the ‘Control of Noise at Work Regulations 2005’ will determine whether personal ear protectors are required in the workplace or not, and the noise attenuation required. The relevant standard for the ear protectors is BS EN 352 Part 1.

In providing hearing protection, employers should select protectors which are suitable for the working environment and should consider how comfortable and hygienic they are. Like other PPE, hearing protection will need to be compatible with other PPE (eg hard hats, dust masks and eye protection) worn by workers.

Employers may also wish to provide a range of protectors to allow employees to choose ones which suit them.

Bearin mind that the theoretical attenuation is rarely achieved and it is therefore necessary to over-specify the protection. When selecting hearing protection, use the detailed noise assessment to determine the attenuation required at High, Medium and Low frequencies and match this against suitable prod cts. Bear in mind that where ear plugs are used, training will be needed to ensure that they are used correctly. Where ear defenders are used it should be ensured that users do not use music headphones or buds simultaneously. For high noise environments, it may be appropriate to specify both plugs and defenders.

Hand and arm protection

Most work requires a degree of manual dexterity and consequently the hands are exposed to a wide range of hazards Risks include cuts, abrasions, heat, cold, chemical contamination, vibration, burns, infection, skin irritation and dermatitis.

Before selecting hand and arm protection, the hierarchy of control measures must be followed. Gloves and gauntlets provide the main form of hand protection against a range of industrial hazards, but other forms of PPE such as mitts, wrist cuffs or armlets may also be used.

In the case of manual handling where there may be a risk of piercing by abrasive, sharp or pointed objects, gloves should be provided where these hazards cannot otherwise be removed, isolated or reduced to an acceptable level. Such gloves are usually made from leather, chain mail, rubber, knitted Kevlar or stout canvas. However, gloves should not normally be worn where there is a risk of them being caught in machinery.

Where chemical exposure is a hazard, and the risk extends to contact with the arms, gauntlets should be specified rather than gloves.

BS EN 14328 is the standard for gloves and armguards protecting against cuts by powered knives while BS EN 407 contains the specifications for gloves intended to protect against thermal risk such as heat and/or fire. BS EN 374 Part 1 covers gloves for protection against chemicals and microorganisms. BS EN 511 covers gloves for protection against the cold. BS EN 388 covers the specification of gloves against mechanical hazards.

Foot and leg protection

A wide range of safety footwear is available providing protection against many hazards to the feet or legs including crushing, slipping, piercing, temperatures, electricity, chemicals, cutting, and chopping. The relevant standard for safety footwear is BS EN ISO 20345. BS EN ISO 17249:2004 is the standard for chainsaw footwear. Depending on the hazard various PPE options may be appropriate including safety boots and shoes with protective toe caps and penetration-resistant mid-sole; gaiters; leggings; and spats.

Body protection

The Regulations’ definition of PPE excludes ordinary working clothes and uniforms which have no specific protection for the wearer. However, body protection may be required for extended periods of work outdoors to protect against the weather, and to ensure high visibility during work where there is mixed vehicle and pedestrian traffic (see BS EN 471 + A1 ’High-visibility Warning Clothing for Professional Use’).

PPE for the body may also be required where workers are exposed to extremes of temperature (whether outdoors or indoors), as well as chemical or metal splash, spray from pressure leaks or spray guns, impact or penetration, contaminated dust, excessive wear, entanglement of own clothing or the risk of drowning.

When choosing body protection the following factors should be considered:

- Thermal comfort, for example, due to sweating;

- Cost and practicality of cleaning;

- Emergency procedures, such as buoyancy or the need to be identified or spotted in hazardous situations;

- Level of hygiene control required;

- Level of personal contamination;

- Personal preference;

- Restriction of movement;

- Storage;

- Temperature and humidity fluctuation;

- Whether the worker is involved in a process that is wet or dry.

Respiratory protection

This covers equipment ranging from breathing apparatus and positive pressure powered respirators through to protective hoods, close fitting full face respirators, half mask respirators and disposable face masks. It is always essential to select the correct equipment both for the risk and the individual and to ensure there is adequate training in its use. It should be noted that the only form of respiratory protection which is suitable for work in a confined space is breathing apparatus, as other forms of respiratory protection do not provide a source of air or oxygen. Face fit testing requirements apply to all close fitting respirators.

Height and access protection

This range of protective equipment is very wide and includes body harnesses, fall-arrest systems, rescue lifting and lowering harnesses, energy absorbers and lanyards.

Such PPE is specialised and requires thorough training by competent persons, in user checks as well as correct use.

Equipment will require periodic inspection by a competent person and anchorage points will normally require periodic testing.

Skin care: ‘Barrier’ creams

Some occupations are prone to skin disease caused by contact with substances such as cutting oils; chemicals, degreasants, glass-fibre and some horticultural agents (eg slug pellets). The main condition is dermatitis, in a variety of forms.

The use of barrier creams, although traditional in many occupations, should not be considered as personal protective equipment. It provides negligible protection and is unlikely to be effective in preventing contact dermatitis. The benefit of barrier creams is in preventing dirt from becoming so ingrained that it is difficult to remove.

A properly implemented skin-care hygiene programme, including barrier creams, emollient and skin-conditioning creams can help protect and replace the natural skin oil which is otherwise removed by degreasants and solvents. Before undertaking this, advice should be sought fromindependent skin-care specialists or a dermatologist.

Free download: Preventing occupational skin disorders: skin care best practice

Key Actions

Employers should:

- Carry out a risk assessment of the workplaces and work activities they are responsible for and through implementation of the risk assessment findings, remove or, as far as is reasonably practicable, reduce the risk of the identified hazards causing harm to workers or others who may be present in the workplace;

- Provide PPE where other means fail to reduce the risk presented by hazards in the workplace to an acceptable level;

- Carry out an assessment to identify the most appropriate types of PPE for use in the workplace.

Where PPE is required it must:

- Be appropriate for the risks and for the working environment;

- Take account of the user’s health, ergonomic, physical and other factors adequately control the risk presented by the hazard without increasing overall risk experienced by the worker;

- Be supplied and replaced free of charge;

- Comply with relevant legislation implementing the European Directives concerning the design and manufacture;

- Where reasonably practicable provide a range of PPE to allow workers to choose the equipment that best suits their working environment and routines, but always ensure that the alternatives made available provide the level of protection required;

- Provide training, instruction or information, including refresher training and demonstrations, as appropriate in the use and care of the PPE provided;

- Ensure face fit testing is undertaken for close fitting respiratory protective equipment;

- Establish a system of recording the issue of PPE and of monitoring, examination and repair for PPE and to allow for the reporting of missing or lost items.

Employees should:

- Correctly use any PPE provided as directed and in accordance with any training, instructions or information they have received;

- Return PPE to its storage place after use unless agreed otherwise with the employer;

- Take care of PPE;

- Report defects or loss of equipment as soon as they become aware of them.