Keeping drivers safe while coupling and uncoupling large goods vehicles is a challenging task. Andy Melachrino looks at how the process can be done safely.

Drivers of large goods vehicles face many risks as they go about their daily business, many of them while they are out on the road.

Drivers of large goods vehicles face many risks as they go about their daily business, many of them while they are out on the road.

But they also face risks both before and after they set off on their journeys. Prominent among these is the process of coupling and uncoupling their tractor unit and trailer in a transport yard.

This is a very important task, one that cannot be avoided. But, with such heavy machinery and equipment involved, how do you make sure those doing it are kept safe?

At Dairy Crest, drivers undertake more than 750,000 coupling and uncoupling procedures every year, so ensuring each one is done correctly and safely is really important.

Over the years the company has significantly improved its safety performance, but is continuously looking for new ways to reduce risks.

On 3 June, IOSH held a workplace transport safety event at Donington Park racing circuit in Leicestershire, which was jointly organised by its Food and Drink and Retail and Distribution groups. It included live demonstrations involving large goods vehicles, with coupling and uncoupling techniques among them.

It is IOSH’s belief that all workers should be covered by a culture of care in all industries. Its Food and Drink Group is keen to ensure that all people involved in the industry benefit from that culture.

The event allowed the group to share best practice and learn new ideas to take back to our respective businesses. Among those new ideas was ensuring safe practices when coupling and uncoupling.

Many safety and health practitioners in the Food and Drink Group, including myself, are responsible for ensuring those who couple and uncouple large goods vehicles are safe. This is a dangerous process, which can lead to incidents that may cause injuries.

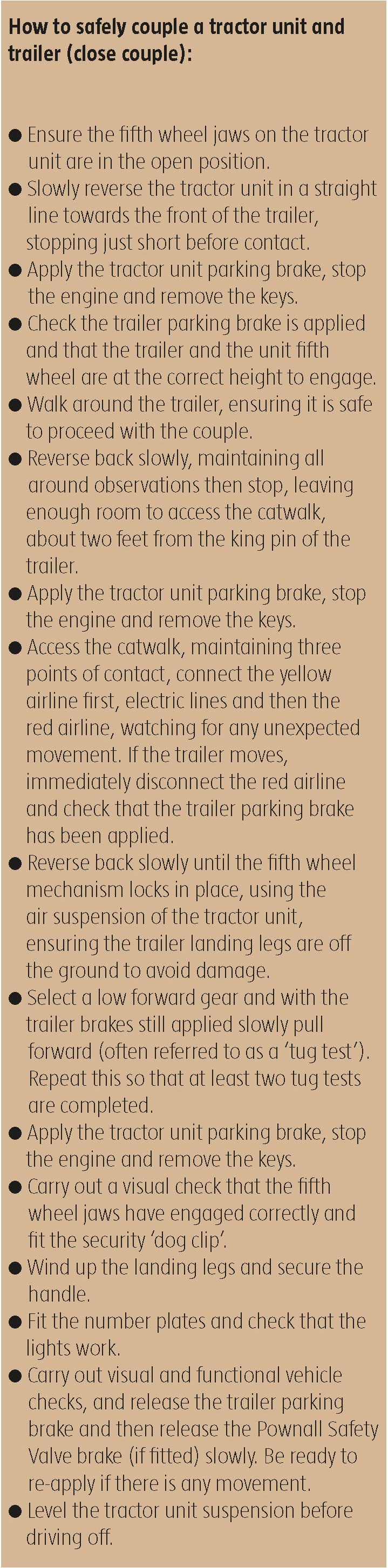

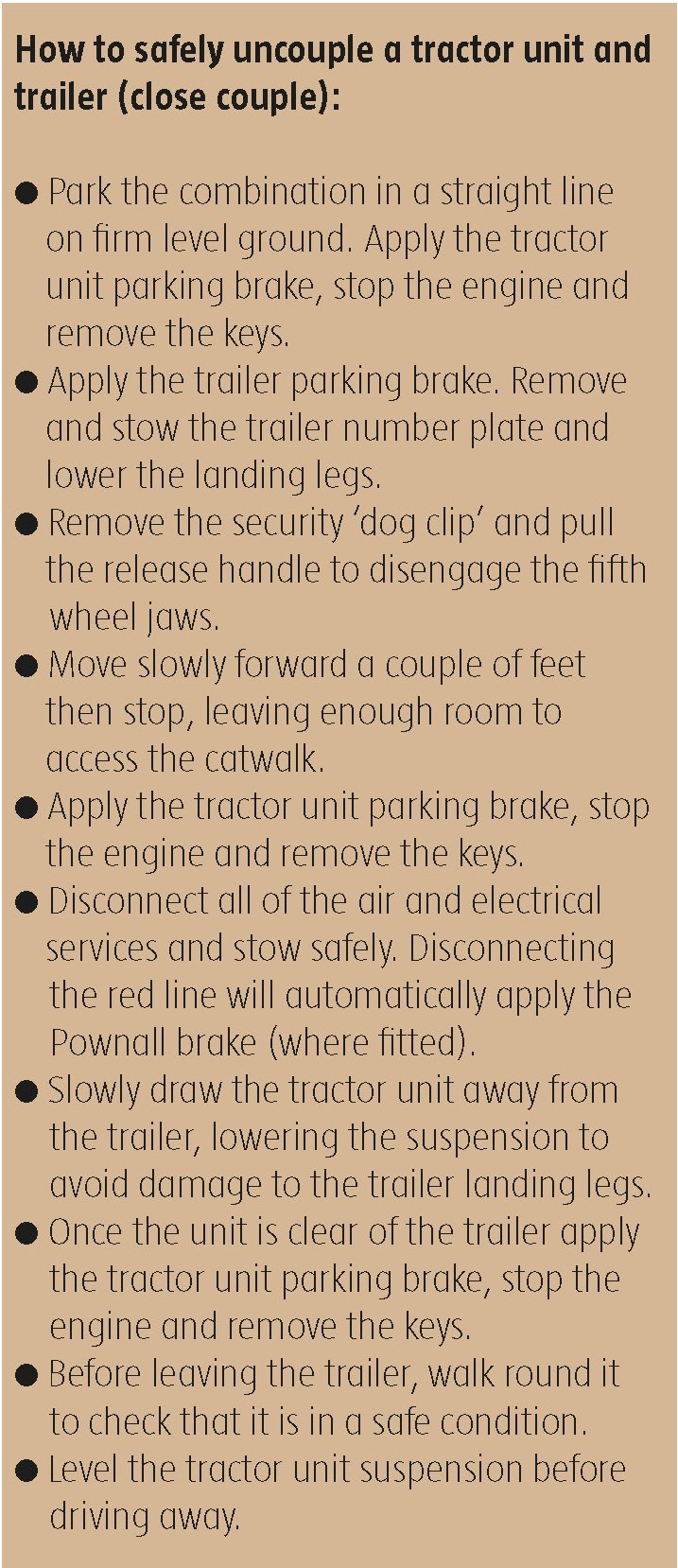

Dairy Crest has worked hard to minimise the rate of ‘dropped trailer’ incidents in which the tractor unit becomes separated from the trailer. The process of coupling and uncoupling is one that is safe when done properly, (see boxes) so the company wanted to know why incidents could happen.

Transport yards are busy places where there are a number of potential hazards; a driver who is coupling or uncoupling a lorry can easily be distracted. Any such distraction can lead to them accidentally missing one of the vital steps in the coupling or uncoupling process – for example, not activating the tractor unit or trailer parking brakes, or ensuring the fifth wheel is really locked into place prior to moving off.

Dairy Crest has also found that tiredness and perceived time pressure can also be a cause of incidents, with drivers losing concentration during the process. LGV drivers in industry spend many hours on the road, which requires a great deal of concentration and can make them tired. They are also often up against it when delivering to stores, which can bring about time pressures.

To cut such incidents, the company has looked at introducing many new features. One of these was the introduction of the ‘golden rules’ booklet, which has been designed by drivers for drivers. This covers the essential safety steps in the process and it is their bible, something they keep with them in their cabs.

To cut such incidents, the company has looked at introducing many new features. One of these was the introduction of the ‘golden rules’ booklet, which has been designed by drivers for drivers. This covers the essential safety steps in the process and it is their bible, something they keep with them in their cabs.

Dairy Crest allows drivers to complete the coupling or uncoupling steps in the order they are used to, provided they follow the key safety principles in the ‘golden rules’.

The company has also produced a DVD, which focusses mainly on the distractions challenge, highlighting what can go wrong, but importantly how to ensure it is always done safely. This DVD, together with our golden rules, has become a key part of Dairy Crest’s driver training and induction process.

Meanwhile random auditing is conducted regularly to make sure that those involved in coupling and uncoupling are doing it properly.

The company is also piloting some new technology which can help to further improve safety when drivers are coupling up large goods vehicles, for example, a system to ensure the fifth wheel is locked in place, which of course does not bypass the need for that important visual check as part of the process. Safety and health is an investment, not a cost.

The coupling and uncoupling of large goods vehicles is always going to be a task which has risk involved. But by putting in place robust safety management procedures it is possible to minimise that risk and safeguard workers. Dairy Crest’s improvement programme continues and the company always welcomes collaboration and the sharing of good practice with other organisations.

Andy Melachrino is vice-chair of IOSH’s Food and Drink Group and head of Group Health and Safety at Dairy Crest Ltd

The Safety Conversation Podcast: Listen now!

The Safety Conversation with SHP (previously the Safety and Health Podcast) aims to bring you the latest news, insights and legislation updates in the form of interviews, discussions and panel debates from leading figures within the profession.

Find us on Apple Podcasts, Spotify and Google Podcasts, subscribe and join the conversation today!