Writing a sound masking specification

By Niklas Moeller

High percentages of open plan space, low partitions and movable walls are just a few of the trends that make today’s interiors even more reliant on sound masking for speech privacy and noise control. However, a sound masking system’s ability to provide these benefits largely depends on its ability to meet the specified spectrum—or ‘curve’—throughout your facility.

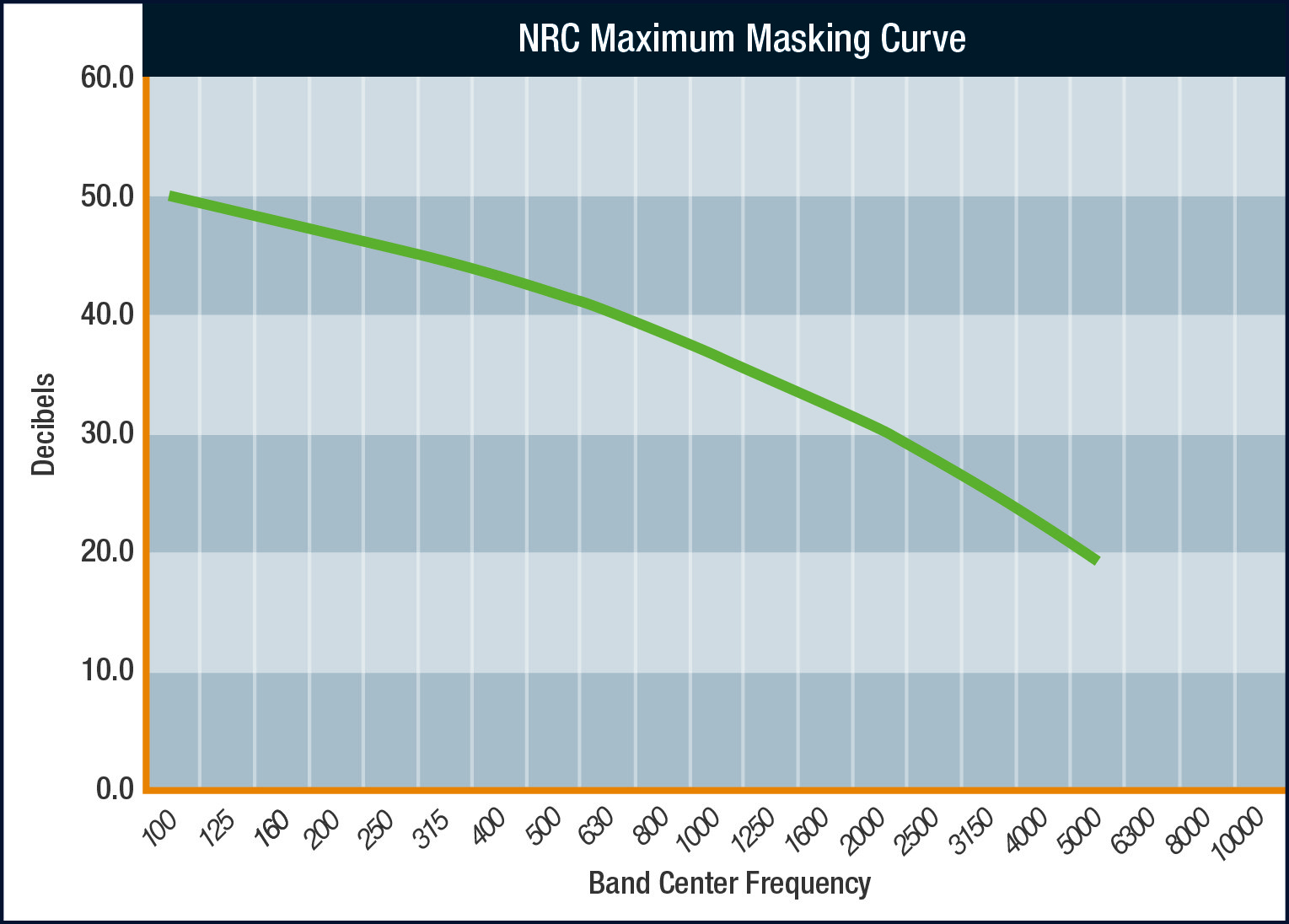

This target should be set by your acoustician or a third party such as the National Research Council, rather than by the sound masking system’s manufacturer or vendor. It is usually defined in third-octave bands and ranges from 100 to 5,000 Hertz (Hz) or as high as 10,000 Hz. For reference, the NRC Maximum Masking Curve is shown here.

After installation, your acoustician or the vendor’s trained technician tunes your sound masking system’s output so that it meets this curve throughout your space. This process is necessary because, regardless of which product you ultimately select, the sound it distributes is affected as it interacts with various elements in your facility’s interior, such as its layout and furnishings.

Your acoustician or technician tunes the sound by measuring it with a sound level meter, analysing the results, and then adjusting the volume and frequency settings accordingly until they meet the specified curve. This process can be time-consuming because they must repeat these steps at each tuning location, but it is essential if you are to derive the full benefit from your investment. In this way, they ensure your sound masking system is providing the intended effects and that they are enjoyed equally by all occupants across your space.

The manner in which your sound masking system is designed provides the foundation for this tuning process. Consequently, it is not only important to specify the desired curve for your space, but also attributes that will facilitate your acoustician or vendor’s ability to meet it, including:

The most important factor is to place an upper limit on zone size. Small zones of one to three loudspeakers covering 225 to 675 ft2 provide a high degree of flexibility. If the sound masking system uses larger zones, numerous loudspeakers must be set to the same volume and frequency, and compromises are made. For example, if the volume needs to be increased to improve the system’s effectiveness in one area, it might be too loud in another, affecting comfort.

To avoid ‘phasing’ (i.e. uncontrollable variations in masking levels), each small zone should have a dedicated masking generator. In addition, each generator should provide a truly random sound (i.e. no repeat cycle). The sound must cover the entire masking spectrum, which is typically 100 to 5,000 Hz, as noted above.

Generally speaking, each decibel decrease in volume can reduce masking performance by 10%. Therefore, fine volume control (in 0.5 decibel steps) should be provided for each small zone, enabling the user to make adjustments for local conditions. If not, the acoustician or technician will be forced to set the volume to a level that’s best on average, compromising effectiveness or comfort at various unpredictable points across your space.

Failing in a key frequency can reduce masking performance by 5%, so the sound masking system should also provide fine frequency control within each small zone. The range should be between 100 to 5,000 Hz and control should be via third-octave adjustment, which is the industry standard and basis for masking targets set by acousticians.

Loudspeaker characteristics

Loudspeaker drivers should be 4 to 8 inches (100 to 200 mm) in diameter and rated from 10 to 25 watts in order to ensure they can generate the low frequencies that are vital to occupant comfort.

Safeguarding the specification

It is also important to appoint a guardian who will ensure that bids meet the established criteria. There are two tools they might find useful:

Drawings

Even if the sound masking systems the vendors propose can provide one to three loudspeaker zones, they may elect to implement them in different ways. Request drawings that show specific components, their quantities and locations to make it easier to compare bids, as well as to identify deviations and discuss those changes with the vendors.

Spec Compliance Form

Also request a compliance form, requiring vendors to indicate their adherence to each aspect of your specification. They should note any deviations, describing how their design differs.

Measured results

Of course, the true gauge of whether your sound masking system is performing as expected is gained from measurements done after installation and initial tuning. Therefore, your specification should also require the acoustician or vendor to provide you with a detailed final report demonstrating that the desired curve is consistently provided throughout your space.

A minimum performance guideline is to require the masking sound to be measured in each 1000 ft2 (90 m2) open area and each closed room, at a height between 1.2 to 1.4 meters (4 to 4.7 feet) from the floor (i.e. at ear height where occupants experience its effects, not directly up at the loudspeaker), and adjusted within that area as needs dictate. Some sound masking systems can adjust for smaller areas, but this is an acceptable baseline.

It will be impossible to achieve perfection in every tuning location, so you should also specify a ‘tolerance’ that indicates by how much the volume is permitted to deviate from the goal. Masking volume should be consistent within a range of ±0.5 dBA (i.e. plus or minus 0.5 A-weighted decibels) or less, giving an overall range of 1 dBA. Permitting a broader range will profoundly impact speech intelligibility; for example, ±2 dBA gives an overall range of 4 dBA, allowing occupants to understand up to 40% more of a conversation in some areas than they can in others. That said, ±2 dB variation is a reasonable expectation in each frequency band. Note that this is a different requirement from that related to volume.

If there are any areas where the masking sound is outside tolerance, the report also should clearly identify the location and reason (e.g. noise from mechanical equipment or HVAC).

For a sample of a performance-based sound masking specification, see www.soundmaskingspecs.com.

Niklas Moeller is the vice-president of K.R. Moeller Associates Ltd., manufacturer of the LogiSon Acoustic Network sound masking system (www.logison.co.uk). He also writes an acoustics blog at soundmaskingblog.com.

Writing a sound masking specification

By Niklas Moeller High percentages of open plan space, low partitions and movable walls are just a few of the

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

The sound of silence

How can we reduce and prevent occupational hearing loss? UKHCA Conference 2023

UK Hearing Conservation Association reveals details of second annual conference