Right now, Thames Water is a £2bn turn over company and is known for its massive infrastructure projects, supplying an essential service to a quarter of the UK’s population, the way it embraces sharing and supporting others and its performance outcomes year after year. It is also known for its leading health & safety initiatives, but it wasn’t always this way.

In 2013 Thames appointed a new H&S lead to turn around its Health & Safety performance and become a leading force for good in the utilities sector. Karl Simons still sits at the H&S helm of this super tanker of a business and explains the foundations laid in advance of its major five-year investment programme titled AMP6, that would see a radical shift in direction and lead to outcomes never seen by a major capital programme before.

SHP caught up with Karl, who now commands the position of Chief Health, Safety & Wellbeing Officer at Thames, to ask him what’s happened…

Before we get into what happened, firstly tell us how did it all start?

Karl Simons (KS): “I recall getting a phone call whilst I was at the time working on a gas rig in the Philippines ocean supporting an international oil, gas and minerals business, inviting me to return to the UK and have a chat with the CEO of Thames Water. It was a great opportunity and the challenges and vision set out, by the then boss, were pretty exciting, so I jumped at the chance when the job was finally offered.

Karl Simons (KS): “I recall getting a phone call whilst I was at the time working on a gas rig in the Philippines ocean supporting an international oil, gas and minerals business, inviting me to return to the UK and have a chat with the CEO of Thames Water. It was a great opportunity and the challenges and vision set out, by the then boss, were pretty exciting, so I jumped at the chance when the job was finally offered.

“I was told Thames had suffered from a series of major incidents at the time, which was clearly totally unacceptable to the main board and executive team, so as soon as I got in the door, my boots were pulled on and I got out onto the sites. Any H&S Director will tell you that on entering a new role in a major safety critical organisation, you need to start by listening carefully to the ground.”

What did you find?

(KS): “Firstly how much I underestimated the risks inherent within the water industry. It is hugely complex with massive reservoirs, some over 10 miles around, treatment works storing cocktails of dangerous chemicals and toxic gases, underground storage reservoirs containing pure potable water and then a vast network of centuries old water mains under some extreme pressure. All this to simply enable people to turn on their taps! Then we had a wastewater side that had similar complexities in reverse.

“Secondly my team of safety, health, systems and training professionals that had lost their voice and were totally undervalued for the service they provided. I had seen this before upon entering other major companies I’ve had the pleasure of leading, so this wasn’t new for me but is always disappointing to see. A high performing health & safety team is a thing of wonder to watch and is crucial towards supporting an open and engaging culture in a company. You should see this dynamic and creative team in action nowadays, they truly are superb!”

What about the health & safety risks?

(KS): “What was evident was the people working there were highly passionate about the service they provided to a quarter of the UK’s population that relied on them. From a H&S risk perspective, although there were subtle differences in process and the types of chemicals and gases used from other industries, which I needed to learn, I knew the key was to establish a framework that would enhance risk visualisation, set out the engagement streams, provide governance over standards and above all make challenging acceptable.”

What do you mean?

(KS): “Ok, so if you want everyone to go home safe and well at the end of every day, you need to have everyone behaving in a way that supports that. But we are humans, so we have slips and lapses in concentration, we make errors in our judgements and we all make mistakes at times. This means we must have a culture where we rely on each other and this means people intervening and speaking up when something is not right, or you observe someone making a mistake.

“Now there really are two reasons people don’t challenge unsafe acts or conditions. Firstly they don’t feel empowered, they think ‘is it my responsibility’ or they feel they don’t have permission and secondly, and more importantly, fear of reprisal. In other words, they worry about what the person the other side is going to say back to them if they do speak up. What if they turn around and say, ‘what’s it got to do with you’ or ‘are you qualified in my job’. Within the company there wasn’t really a culture that encouraged challenging when I arrived, so we needed to tackle that first.”

So, what’s AMP6?

(KS): “The water industry works in five-year cycles and, since privatisation, this was the sixth of those (2015-2020). It’s where we set the price limits for our customers for that period, so bills don’t fluctuate. It’s also an opportunity for the water clients to review and refresh the contracts of the good organisations you wish to continue working alongside you or appoint new companies to work with in the future.”

What was the vision?

(KS): “I recall sitting down with the procurement team, who already knew we needed to do things differently, and we set out that we not only would get the right companies, but also the right people in key leadership positions, to form an alliance where all companies would share the gain and share the pain.

“Key to this was placing H&S at the forefront of the procurement decision making process. We set out a process which had three key steps, a CEO and team panel interview, a series of site visits and a two-day workshop’s. But what was truly different was the behaviours we brought in and, in each stage, I was flanked by behavioural psychologists. They knew nothing about construction, but they knew how to read people, and this truly changed the way we looked at individuals and the outcomes we got were very different indeed. I learned a lot in this stage.”

What happened next?

(KS): “Upon appointment of the seven contracting partners in the alliance, to work with Thames, we called the alliance ‘eight20’. I brought together the H&S Directors who were the top H&S Executives in each of the partner organisations and we agreed we were going to have one single way of working, taking the best from each of us and piecing it together to form an exemplary way of working that would change the way construction projects would be delivered on this massive programme!”

(KS): “Upon appointment of the seven contracting partners in the alliance, to work with Thames, we called the alliance ‘eight20’. I brought together the H&S Directors who were the top H&S Executives in each of the partner organisations and we agreed we were going to have one single way of working, taking the best from each of us and piecing it together to form an exemplary way of working that would change the way construction projects would be delivered on this massive programme!”

What was the response?

(KS): “They said it was refreshing to have a client that wanted to simplify and, more importantly, listen and learn from what they did best. I mean these were big companies (Skanska, Balfour Beatty, MWH, Costain, Atkins, Veolia & IBM), but each H&S Director had the maturity to see the opportunity and was fully on board with the approach, and so we got to work together.”

What were the outcomes?

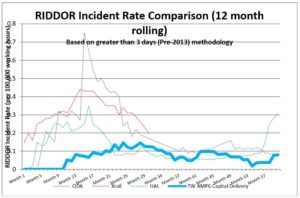

(KS): “My focus wasn’t on the outcomes in the early stages, as I knew that would simply be a bi-product of our work, it was the inputs I was interested in. You see I knew any new major project is at its most vulnerable in the first year of establishment. We had seen from previous high-profile major capital programmes, such as the Olympics, Crossrail and Heathrow T5, there was always a spike in incidents in the first 18 months. This was due to a melting pot of different cultures coming together at one time which leads to inconsistency in standards and compliance. We inducted over 8,000 people to work across the portfolio that first year, but the hard graft was put in to established a single way of working all would align to and together we created a management system littered with standards and controls that would benefit everyone collectively.”

What initiatives did you implement to get culture aligned?

(KS): “There were lots of initiatives, but firstly upon induction we gave everyone Thames Water workwear and PPE. It didn’t matter, and I certainly didn’t care, which parent company you came from. On this programme everyone was treated equally, and everyone was issued with our gear, whether a Tier 1 major company or a Tier 4 SME in the supply chain, everyone wore our orange PPE and workwear.

“Now I knew this would increase our risk portfolio as the public would instantly see a massive increase in visibility of Thames Water, as now we would have tens of thousands of contractors on the streets and on our sites all wearing our workwear and driving vehicles with our name on it, but this made a family feel and remember our customers have a lifetime relationship with Thames Water, so our contractors needed to feel we viewed them as one of our family and valued them as one of our own.”

Was mental health included in the initiatives?

(KS): “Health, both physical and mental, is as important as safety and the philosophy of alignment was absolutely embedded and sustained here and again there was a plethora of initiatives. One exciting new initiative we agreed to introduce for all our own employees, and for anyone working in our alliance, was access to an annual free confidential personal medical assessment that involved reviewing a person’s physical and psychological health. To get agreement and support from my peers on introducing this across the Alliance was spectacular! Just think about that, we had major companies offering their people on our programme something that wasn’t offered to their peers in their wider parent company!”

How did you sustain the contractors keeping the focus on H&S?

(KS): “We have a group in Thames called the Health & Safety Leadership Team, where every month Senior Executive Directors from each of our Major Tier 1 organisations give their time to meet collectively with me.

“It is always chaired by a member of our supply chain and this forum is instrumental and very powerful, as from the very start of AMP6 we agreed, they own the Thames Water Essential Standards. These are a suite of contractual obligations that all our supply chain must price to and work to. The sparks soon start flying when you give empowerment to a group of leaders that can see they can personally shape the standards and expectations of a major client organisation. My job is simply to provide some technical input and overall H&S direction on behalf of the Thames Executive Team, who I report into every month.”

So, what were the outcomes of all this effort?

(KS): “The five-year, £5bn investment programme finished on 31 March 2020. We have, through our Alliance partnership, achieved a staggering outcome with no spike of injuries in the early years, frequency rates that I certainly have never seen before on other major capital delivery programmes and of course zero fatal or life changing injuries.

“The credit for the success of the programme goes to the thousands of managers that put their teams to work safely every day and the tens of thousands of operatives and office workers that looked after each other and took safety and health seriously every day. I have certainly learned a lot from them.”

The Safety Conversation Podcast: Listen now!

The Safety Conversation with SHP (previously the Safety and Health Podcast) aims to bring you the latest news, insights and legislation updates in the form of interviews, discussions and panel debates from leading figures within the profession.

Find us on Apple Podcasts, Spotify and Google Podcasts, subscribe and join the conversation today!

Karl Simons (KS): “I recall getting a phone call whilst I was at the time working on a gas rig in the Philippines ocean supporting an international oil, gas and minerals business, inviting me to return to the UK and have a chat with the CEO of Thames Water. It was a great opportunity and the challenges and vision set out, by the then boss, were pretty exciting, so I jumped at the chance when the job was finally offered.

Karl Simons (KS): “I recall getting a phone call whilst I was at the time working on a gas rig in the Philippines ocean supporting an international oil, gas and minerals business, inviting me to return to the UK and have a chat with the CEO of Thames Water. It was a great opportunity and the challenges and vision set out, by the then boss, were pretty exciting, so I jumped at the chance when the job was finally offered. (KS): “Upon appointment of the seven contracting partners in the alliance, to work with Thames, we called the alliance ‘eight20’. I brought together the H&S Directors who were the top H&S Executives in each of the partner organisations and we agreed we were going to have one single way of working, taking the best from each of us and piecing it together to form an exemplary way of working that would change the way construction projects would be delivered on this massive programme!”

(KS): “Upon appointment of the seven contracting partners in the alliance, to work with Thames, we called the alliance ‘eight20’. I brought together the H&S Directors who were the top H&S Executives in each of the partner organisations and we agreed we were going to have one single way of working, taking the best from each of us and piecing it together to form an exemplary way of working that would change the way construction projects would be delivered on this massive programme!”

What a very interesting article to read and professional interview with karl simons from Thames Water regarding health and safety at the workplace. He was very thorough in his explanations on every aspect of both mental health and wellbeing in the industry and how important it is throughout the various industries that peoples wellbeing is of the uttermost importance in this day and age to succeed.