Decommissioning Sellafield

Decommissioning Sellafield: A behind the scenes look at the technology being used

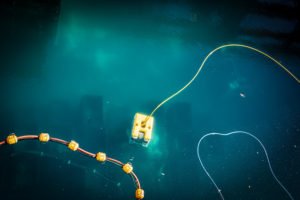

Robotic submarines are being used to safely inspect, clean and retrieve debris from radioactive fuel storage ponds.

The Sellafield nuclear fuel reprocessing and nuclear decommissioning site, close to the village of Seascale on the coast of the Irish Sea in Cumbria, is said to be one of the most contaminated industrial sites in Europe.

The Sellafield nuclear fuel reprocessing and nuclear decommissioning site, close to the village of Seascale on the coast of the Irish Sea in Cumbria, is said to be one of the most contaminated industrial sites in Europe.

It was the site of the first commercial nuclear power station anywhere in the world and manufactured plutonium for the atomic weapons programme in the 1950s.

The vast majority of what remains of its toxic legacy from the early years of the nuclear age is crumbling away now. The buildings that do remain standing are near-derelict, but the site itself is home to decades worth of accumulated radioactive waste.

The site’s operators are working to make the most dangerous areas of the site safe, but how do you clean up areas where it’s too dangerous for humans to venture?

ROV vehicle

The team is using hi-tech underwater robots, specifically designed for cleaning up the radioactive debris from the depths of a 66-year-old open-air nuclear fuel pond, the First Generation Magnox Storage Pond, located at the heart of the site.

The pond has something of a reputation on the site and in surrounding areas. It has a nickname, which can’t be published for security reasons, and is seen as a big, dirty, problematic radioactive beast that encapsulates the challenge in dealing with the legacy of its past.

It was used to store used nuclear fuel taken from the UK’s earliest reactors prior to it being ‘reprocessed’ and is classed as the second highest hazard at Sellafield, behind the Magnox Swarf Storage Silo.

During its 26 years of full operations, the pond processed around 27,000 tonnes of nuclear fuel.

Although the facility ended its operational life some decades ago it still holds much of its corroding and decaying radioactive waste inventory.

Built to cope with the acidity of the water, this is where the remotely operated underwater vehicles (ROV) come in, controlled by operators comfortably situated a safe distance away from the treacherous area.

Decommissioning Sellafield

Decommissioning Sellafield

The team’s focus is on decommissioning the pond, meaning removing its waste inventory equipment before demolishing it, a project which is expected to take around 20 years to complete.

The inventory consists of nuclear fuel, old in-pond equipment, and a material known as ‘sludge’ – an unplanned by-product made up of fuel fragments, naturally-occurring pond algae and wind-blown debris. The material is highly radioactive.

The ROVs enable remote access to difficult and hazardous areas without the use of personnel, which has obvious safety benefits.

The ROVs are equipped with tools like cameras and manipulators and carry out tasks like picking up fuel rods from the pond floor and placing them into fuel skips.

Some of the camera drones are as small as the palm of a hand and allow video access to very congested and hazardous parts of the ponds that have not been seen for over 40 years.

In contrast, the larger ROVs are around the size of a washing machine. They are required to carry out the more heavy-duty tasks such as sucking up the sludge from the bottom of the pond or removing the old fuel rods.

Robotics

It’s not just underwater where technology has been utilised across the site. The one remaining nuclear chimney is in the process of being removing.

During that process, a specially adapted drone was flown up the centre of the tower, measuring the radiation levels and enabling a 3D radiation map to be drawn, highlighting the hazardous areas.

Of course, when dealing with such dangerous materials, the machinery needs to be tried and tested. The possible unreliability of new equipment would be too much of a risk.

For that reason, several robots that were built for a car production line have been adapted for use in lifting and demolishing any materials which are deemed too dangerous for humans to be in the proximity of.

Decommissioning Sellafield: A behind the scenes look at the technology being used

Decommissioning Sellafield is a huge and dangerous task. To mitigate the risk, robotic submarines are being used to safely inspect, clean and retrieve debris from radioactive fuel storage ponds.

Ankit Kumar

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Drug and alcohol testing in a UK airport environment

Unleashing the power of emerging technologies in EHS

Passing the baton – Meet the 2024 IOSH President

The

The  Decommissioning Sellafield

Decommissioning Sellafield