Climbing the zero harm ladder

By Robin Stowell

I start by stating my support of Mark Ormond in his recent articles “Safety target: zero harm” and “Five reasons why you’ll never achieve zero harm” and judging by the online responses, so do the majority of safety practitioners. The failure of many zero harm concepts come from their simplification and interpretation for management boards into a KPI target, or even worse, a marketing slogan. Any incident that undermines this mantra is highlighted and disproportionately investigated, taking up excessive resources and creating a culture of fear. Simply put, the implementation of a zero harm policy is likely to have unintended consequences of re-enforcing the organisational characteristics that drive poor safety performance (actual results, not statistical lies).

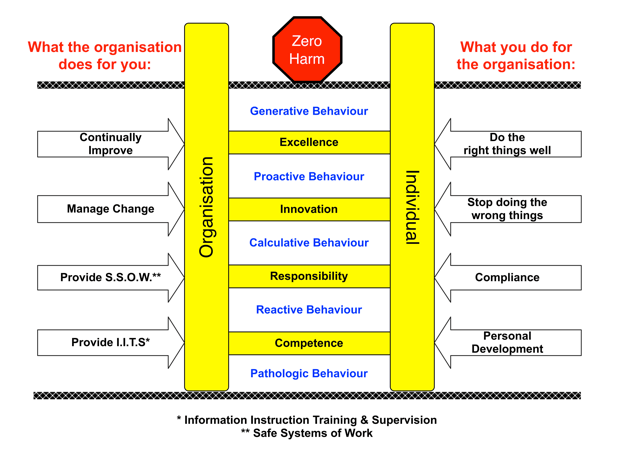

What is missing from the zero harm argument, and allows the ‘Absolute Zero’ camp to challenge Mr Ormond’s views is an integrated understanding; a model that incorporates organisational values, safety management systems and individual actions. In doing so it is possible to realise that ‘behaviours’ are not only an individual aspect, but also organisational and they are intimately linked.

I propose a different way of communicating zero harm concepts to both the organisational hierarchy and the workforce exposed to occupational risks. The idea of a Zero Harm Ladder developed from working in the wind turbine sector, where accessing and climbing turbines by ladder is day-to-day business for technicians, but also one of the more significant risks.

The purpose of the Zero Harm Ladder is to identify the organisational and individual steps that are needed to reach each ‘value’ rung and move up the behaviour zones. However, this is a two-footed approach and each rung can only be reached if both organisation and individual steps are achieved and work together at the same level. When a mismatch occurs, only the lowest behaviour on either side should be expected. For example, an individual who is willing to comply with safe systems of work but has not been provided sufficient information, instruction, training or supervision will not be able to step onto the ‘Competence’ rung and the resulting behaviour will be ‘Pathologic’. Similarly, an organisation with a well-developed safety management system, which effectively manages change, will only achieve ‘Reactive’ behaviour if an individual does not comply with safe systems of work.

It is worth noting that for the value ‘Innovation’, rather than adding new processes and procedures, my preference is to identify the wrong ones and stop doing them. Getting the organisation to accept this and manage such a change can be a challenge, but once achieved you will be left with the right processes which, if done well, will lead to ‘Excellence’.

Correct application of this model is to use it to examine specific circumstances rather than being a global statement of intent. Applied as a management tool it can aid planning, implementation and incident investigation. It is transferable between industries and adaptable to specific company requirements and definitions.

Zero harm (or whatever the concept name) at the top of the ladder can be reached but only within the boundaries of defined organisational tasks and people, not as a generic catchall, KPI or slogan. Try assessing yourself and your organisation for the next task you do. How far up the ladder are you – what needs to be done to take the next step?

Robin Stowell CEng CMIOSH is Managing Director of Conversulting Ltd; providing consultancy and training services to the renewable energy industry.

Climbing the zero harm ladder

By Robin Stowell I start by stating my support of Mark Ormond in his recent articles “Safety target: zero harm”

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Safety Leadership: From virtual safety to real safety

Key updates: Common assessment standard and public procurement

Workers facing uncertain future coupled with health and safety risks, new IOSH report says