Occupational health is a key priority for business.

The Health and Safety Executive (HSE) has, since the introduction of the Health and Safety at Work etc Act 1974, seemed to have been concentrating more of its efforts on managing the safety rather than health aspect of its remit. While there have been some adjustments over time for what is recorded as a workplace fatality, the organisation’s focus has been successful in reducing annual workplace fatalities from around 650 in 1974 to 144 in 2015/16 (or under 100 when adjusted to align with 1974 reporting requirements).

The HSE rightly promotes the important advances that have been made, proudly stating a positive message about the UK’s health and safety record being ‘the envy of much of the world’ and one that continues support innovation and productivity. As the organisation makes clear, its challenge going forward is to now improve even further on this impressive record. A key part of that process will see an increasing focus on occupational health to ensure British employees are given maximum protection to lower the risk of suffering a work-related illnesses, enabling them to do their jobs within the best possible environment. With 1.2 million people in 2014/15 suffering from an illness they believed was caused or made worse by their work, and thousands dying from work-related cancers – now is the time to act.

There is also a legal and moral responsibility on employers to do whatever is reasonably practicable to support this agenda and ensure they are taking all the appropriate measures to prevent work-related ill health.

In addition to compliance with general duties under the Health and Safety at Work etc Act and the Management of Health and Safety at Work Regulations 1999, some more specific legal duties are relevant to the common health problems. For example:

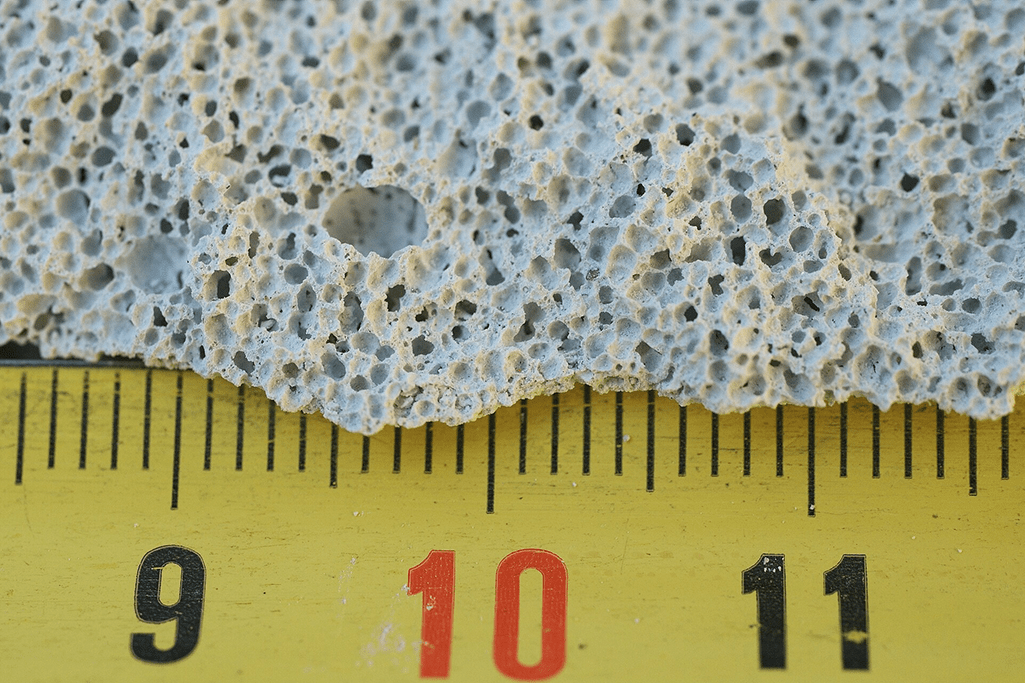

- Control of Substances Hazardous to Health Regulations (COSHH) and Approved Code of Practice deals with, among other things, substances that cause asthma. This includes an extensive list ranging from chemicals used for industrial processes to everyday items found in a working environment such as the by-products of certain food types, as well as paint additives and office cleaning products. COSHH also covers fumes, dusts, vapours, gases and even nanotechnology.

- Manual Handling Operations Regulations are relevant for many musculo-skeletal disorder (MSD) problems. Identifying work-related health risks may not be straightforward, but there are a number of sources that can be used.

In order to safeguard workers, the cause of occupational health risks must first be known. Once the main risks, which include musculo-skeletal disorders as well as potential complications caused by excessive dust and noise, are determined then action can be taken to risk assess these areas individually in the same way as safety issues.

It is important to determine not only the individuals or groups of individuals which are most likely to be exposed to these risks but also the degree to of this potential exposure and the likely consequences resulting from it. This knowledge will also be useful when recruiting new personnel or during rehabilitation for an employee who has suffered from a work-related health ailment to ensure the working environment does not adversely affect any pre-existing medical condition.

Attendance management or, more specifically, monitoring of sickness absence has increasingly become a major occupational health-related issue with many large employers. Information obtained from more tightly-managed attendance records is often an invaluable resource for a company or organisation’s Safety, Health and Environment (SHE) operation (as well as its Human Resources department) and can be very useful in spotting possible work-related health problems.

Through analysis of these records, a SHE manager can determine if there are certain jobs or parts of the workplace where absence tends to be higher which may indicate the potential of an occupational health risk within an organisation. While some degree of caution needs to be exercised when analysing absence patterns, this can unveil common issues including high levels of back pain or work related upper limb disorder symptoms to be associated with certain types of work.

More detail may be available from medically-certificated absences, which tend to be over seven days, than from self-certificated absence. However, it is important to bear in mind that absence certificates are mainly completed by GPs who have little experience or training in occupational health. Some sensitivity may also be needed about personal information for individuals that is protected by data protection laws.

As with any health and safety problems, the hierarchy of control measures in Schedule 1 of the Management of Health and Safety at Work Regulations should be followed. Where possible, removing the hazard is the best option. Reliance on individual protection through personal protective equipment should normally be a last resort.

There are many examples of successful intervention in HSE guidance. Often the process of managing occupational health only requires good communication between managers and workers. There is usually no need to employ specialist assistance or experts although involvement of occupational physicians and specialists can be cost effective in appropriate circumstances.

When expert advice is needed it may not necessarily mean that medical opinion is required. For many musculo-skeletal disorder problems, for example, the views of an ergonomist might be more appropriate or for an asthma problem, the insights of an occupational hygienist are more likely to carry greater weight.

While there are a small number of occupational safety and health advisers in operation, specialist services in this area are not well developed in the UK at present. The HSE is, however, keen to promote the development of better sources of advice and given its increasing focus in the area of occupational health as the new frontier in developing greater health and safety in UK workplaces, I suspect we will see future growth in this market.

Stress, stress, stress seems to have replaced the mantra of education, education, education yet, no one appears to know what that means, other than, work stress / fatigue accounts for presenteeism and, in the chain of causation in major incidents, results in significant loss of life and serious injuries let alone long-term, on-going or instant loss in productivity where plant destroyed and has to be rebuilt. Even the new International Management Standard understands “Work Exposure Limits” are critical not just in terms of improving health and potentially optimising sustainable productivity but, safety if, simple errors or mishaps to more critical… Read more »

Nigel, I agree with you.