Innovation in Manufacturing

Innovation in Manufacturing: Health & Safety at Müller

Graeme Westland, Head of Health & Safety at Müller UK & Ireland, tells HSE Recruitment Network’s Sophia Darwin about some the innovative projects and programmes that the Müller health & safety function have implemented under his stewardship.

Graeme Westland

Müller UK and Ireland is the biggest milk and ingredients business in Britain, a leading UK yogurt manufacturer and one of the largest UK logistics businesses, with around 10,000 people spread across almost 100 sites. The company comprises three business units: Müller Milk & Ingredients, Müller Yogurt & Desserts and Milk & More. The business develops, manufactures and markets a wide range of branded and private label dairy products made with milk from more than 1,700 British farmers.

Müller is also the seventh biggest food and drink brand in Britain, with its products picked from shelves more than 230 million times each year. The Müller UK & Ireland central safety team is made up of four senior safety managers, all of whom report into Graeme Westland.

The Challenge

At the start of 2012, Müller took over Robert Wiseman Dairies, and in December 2015 the company acquired the dairy operations distribution businesses of Dairy Crest Group plc. As Britain’s largest ever dairy industry integration, the challenge was to unite them together under one strategy, as all companies had widely differing performances, risks and capabilities. Graeme created a five year strategy to significantly improve safety performance and to bring the approaches together.

Underpinning the strategy is the simple philosophy of: “Nothing we do is worth getting hurt for”.

Graeme and the team developed a number of innovative programmes which culminated with the Müller Benchmark Safety Index (balanced scorecard). Embedded in these programmes were an advanced approach for measuring safety performance beyond the usual lagging metrics of Lost Time Injury Frequency Rate (LTIFR) or RIDDOR, along with interactive and engaging campaigns which influenced employee attitudes and behaviours and encouraged (or ‘nudged’) individuals to think differently about safety. These programmes have resulted in significant and tangible improvements in Müller’s safety performance.

Sites with strong BMI performance show strong lost time accident performance.

The Müller Benchmark Index (BMI)

Graeme explained that this is a balanced scorecard to measure safety performance made up of 14 measures of safety activity and metrics, predominantly leading indicators. It also includes health surveillance and compliance which is crucial in determining the effectiveness of safety initiatives.

The Benchmark Index is a key performance indicator in all business divisions. There is a very strong correlation between sites who score well in the index and produce excellent operational and safety performance. “It is a simple, but effective, tool that sites can use to identify where we need to make improvements,” said Sharon Reynolds, Health & Safety Manager for Müller Yogurt & Desserts.

“There’s no secret, the harder you work at preventing accidents, the better your results,” said Martin Watson, Senior Safety Manager for Müller Milk & Ingredients.

Innovative and engaging safety campaigns

“Safety campaigns need to be novel, innovative and memorable to be effective, so that’s what we set out to do,” says Darren Thain, Müller’s Senior Safety Programmes & Performance Manager.

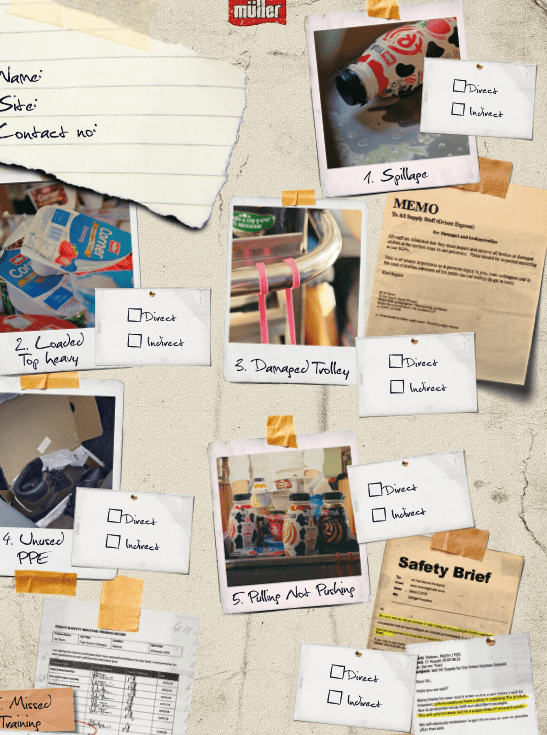

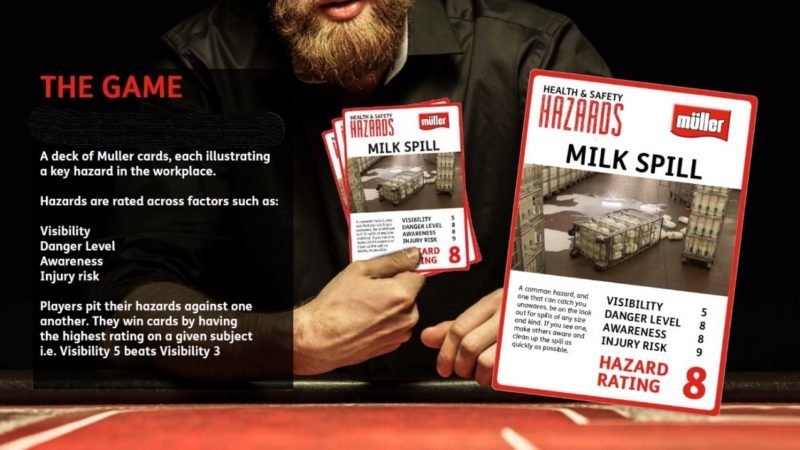

Müller launched two targeted campaigns at specific times of the year to coincide with accident peaks. The first was the ‘Don’t Gamble with Safety’ campaign, which featured a competitive card game alongside a safety movie which were both a hit with the workforce.

The Health & Safety Hazards card game pitted players against one another in hazard assessment, with the highest-rating on any particular category stealing the opponents card. This was rolled out across various sites, with prizes for the winners.

“It was the best safety campaign i’ve ever seen in my 30 years of Dairy operations,” said Paul Notarangelo, Head of Manufacturing, Milk & Ingredients (Scotland).

“It was the best safety campaign i’ve ever seen in my 30 years of Dairy operations,” said Paul Notarangelo, Head of Manufacturing, Milk & Ingredients (Scotland).

The second campaign was a movie enactment, which focused on the causes of injury and understanding root cause. “It was an important message to get across, but in a different way,” said Katie Rodham, Senior Safety Manager, Milk & More.

The key to both campaigns were that they encouraged employees to think about safety in a new way, making memorable links to safety messages that lived on long after the campaign themselves. Graeme was able to find the balance between delivering very serious messages, while making it light-hearted and accessible.

The campaigns were highly effective not only in terms of engagement but also results. This was evident after the campaigns in October 2017 and September 2018 which coincided with the joint safest months ever on record for Müller UK & Ireland.

“The link between our safety campaigns and performance is indisputable”, said Graeme. Overall we have achieved a massive amount with our operational colleagues in the last four years. The team should be very proud. Our Benchmark Index and safety campaigns have made the difference, along with our other programmes. We have reduced our lost time incident rate by over 50% since 2015 and we’re amongst the best in the UK in terms of our safety performance. However we have no intention of resting on our laurels and have even more ambitious and innovative plans for the future.”

Innovation in Manufacturing: Health & Safety at Müller

Graeme Westland, Head of Health & Safety at Müller UK & Ireland, talks about some the innovative projects and programmes that the Müller health & safety function have implemented under his stewardship.

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Company fined as worker has leg amputated

Almost half of UK manufacturing employers have increased spending on workforce health and wellbeing

Bedding manufacturer fined after employees suffer serious injuries

“It was the best safety campaign i’ve ever seen in my 30 years of Dairy operations,” said Paul Notarangelo, Head of Manufacturing, Milk & Ingredients (Scotland).

“It was the best safety campaign i’ve ever seen in my 30 years of Dairy operations,” said Paul Notarangelo, Head of Manufacturing, Milk & Ingredients (Scotland).