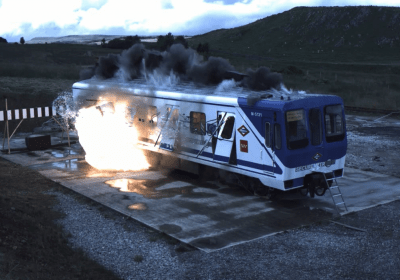

A full-scale test at HSL

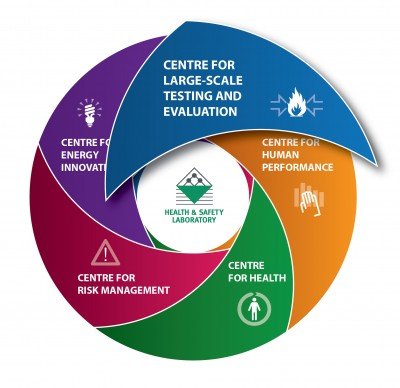

David Johnson heads up the HSE’s Health and Safety Laboratory (HSL) Centre for Large-scale Testing and Evaluation. He speaks to Nick Warburton about its work and how it is supporting industry to enable new technologies.

David Johnson

David Johnson explains that it was the ground-breaking work undertaken by the Centre for Energy Innovation on hydrogen, energy storage and batteries that prompted HSL to forge ahead with the centre he heads up, which has diversified to cover key sectors like aerospace, defence, and security and transport.

“The Centre for Large-Scale Testing and Evaluation has really come out of that. The understanding that we can help across the piece – different sectors and a huge breadth of facilities and technical expertise,” he explains.

“We can help clients understand their problems and provide robust information and data so that they have an evidence base to make informed decisions with regard to their assets, structures and products.”

Recent experimental work certainly supports his assertions, with examples including: impact and fire testing of a nuclear transportation package; empirical work to validate the use of a computational fluid dynamics model for predicting the behaviour of LNG pool fires; comparative performance testing of fibre-reinforced plastic and metallic pipework for refinery applications; and carrying out a range of gas releases to verify and benchmark commercially available gas detector systems.

The Centre for Large-Scale Testing and Evaluation’s modus operandi ranges from testing to existing standards to more cutting-edge, bespoke solutions. With 400 technical experts spanning a multitude of disciplines and a wealth of testing facilities on its 550-acre site, HSL has the skill-base, space and capability to provide the whole piece from designing a test from scratch, through to testing and finally detailed evaluation. This integrated offering is a key differentiator for HSL.

“A sizeable proportion of the work that we do can be complex and it needs to be thought about in a holistic way,” he explains.

“There can be value in having a range of technical discussions upfront. The output of those discussions is a testing protocol and we’ll work with the client to get the data that they require. Our technical diversity allows us to look at things in a multi-disciplinary way.”

Explosives testing and new technologies

The centre covers a wide range of themes: fire and explosion; impact and crashworthiness; explosives testing; batteries and energy storage; process safety; hydrogen and alternative fuels; and general engineering. Johnson explains that this capability can be used for experiential learning, validation of models, understanding consequences of failure and product development. He states that an increasingly sizeable proportion of the work that the centre undertakes is aligned to enabling new technologies.

“It’s about embracing innovation but doing that in a safe way and batteries is a really good example,” he explains.

“What we are doing is conducting tests to characterise and understand the performance envelope so that batteries can be exploited in an advantageous but safe way. That’s a theme that runs through a lot of what we do.”

Johnson admits that innovation can lead to a certain degree of uncertainty but adds that this is why HSL carries out testing to evaluate performance.

“Innovation can lead to a step change in what you might call a conventional health and safety system but what you want to do is innovate while identifying and mitigating any issues or concerns,” he continues.

“Nobody wants an incident or a failure. When you consider that, the best way of going about something is to do it in a proactive and structured way upfront as part of the product development cycle. When you are developing a product, what you don’t want to do is the design work, for example, and for safety to be a bolt-on at the end. Ideally, health and safety considerations should be an integral part of the product development process. Hopefully, you’ll end up with safer product and health and safety system as a result.”

Another important area to highlight is scalability – the ability to conduct small-scale and full-scale testing. One of the many full-scale testing offerings at HSL is the jet-fire facility, which is used to certify passive fire protection (PFP) materials. In order to assist with product development activities, HSL developed a bespoke small-scale jet-fire facility.

This unique facility, designed in-house, allows PFP manufacturers and other parties to test and benchmark products in a convenient, economical way. HSL can now offer clients a fully integrated solution by providing the option to use the small-scale burner to develop products prior to obtaining certification via a full-scale test to ISO 22899.

A jet fire test at the HSL

In many cases, HSL can test a material to destruction as well as simulate real-case incident/failure scenarios. This is where training and experiential learning becomes increasing important. By demonstrating to clients the effects of an incident, HSL argues that it can positively influence human behaviours.

“This is important because when incidents occur, there tends to be an engineering/human interface. If you take people out on site and you show them the failure of a vessel, for example, they can feel the heat and the thud in their chest and we call that experiential learning,” he says.

“What it does is make people see, often the ones that make the really important decisions, the implications and ramifications of their decisions. When they see what can happen when things go wrong, I think that can really drive and change certain behaviours. Health and safety very much starts at the top but needs to be embedded throughout the whole organisation. Experiential learning can be really good in showing and teaching people what can happen.”

The HSL site in Buxton

Another benefit of doing such a broad spectrum of testing is that it provides HSL with the opportunity to transfer knowledge and identify themes across sectors.

“Let’s say we do some aerospace testing and there’s a similar material that needs to be tested for an oil and gas application. Because we do testing for several sectors, it enables us to say, ‘Aerospace does it this way, have we thought about applying that approach, where appropriate, to some of the oil and gas testing?’ It allows us to identify the emergence of new materials, for example composites, in different sectors. We look and see whether we are seeing some of the same issues and concerns around these materials in the different sectors.”

Wrapping up, Johnson returns to the earlier theme of enabling technologies and the benefits of composite materials. HSL has undertaken a lot of work to understand and substantiate the properties and performance of composite materials in comparison to traditional materials that are currently used on plant.

“This comes back to asking, ‘How do we work with clients to understand the advantages of this particular material while also identifying and perhaps mitigating some of the disadvantages?’”

On this point, Johnson concludes by pointing to a research project (which is jointly funded by HSE and industry), which starts next month and will investigate how composites can be used to repair defects on a range of onshore and offshore plant.

“The project will look at the long-term integrity of engineered composite repairs. It’s going to be an 18-24 month programme and will address the key issues and concerns – from both an engineering and human factors perspective. It’s a really exciting area of development and it will be a great opportunity to work collaboratively to improve confidence and enable the safe use of the technology.”

Find out more information about large scale testing and evaluation at the Heath and Safety Laboratory.

Fire Safety in 2023 eBook

SHP's sister site, IFSEC Insider has released its annual Fire Safety Report for 2023, keeping you up to date with the biggest news and prosecution stories from around the industry.

Chapters include important updates such as the Fire Safety (England) Regulations 2022 and an overview of the new British Standard for the digital management of fire safety information.

Plus, explore the growing risks of lithium-ion battery fires and hear from experts in disability evacuation and social housing.

… a nice place for desired big bang