Ear plugs at work – a buyer’s guide

What are ear plugs?

Ear plugs are generally used in the workplace to help protect the user’s ears from excessive noise, however they can be used to protect worker’s ears from the intrusion of water, foreign bodies, dust or excessive wind. Exposure to loud noise in the workplace can lead to loss of hearing and/ or tinnitus (a permanent ringing in the ears).

Unlike ear defenders, ear plugs are inserted into the ear canal, which can offer greater hearing protection; making them a good choice in areas of extreme noise. They are also smaller which can mean they are easier to wear with additional PPE such as goggles and head protection. Ear plugs are often chosen in areas with warmer climates as ear defenders can become uncomfortable in hot weather.

Ear plugs vary vastly; from foam disposable ear plugs, to pre-moulded re-useable ear plugs to silicone custom made ear plugs that can be made for your exact ear canal either by a professional or by using a DIY kit. There are also ear plugs designed for specific tasks, such as within the music and agriculture industries. (See more in the ‘Types of ear plug’ section of this guide).

Understanding hearing protection in the workplace

By law an employer must assess and identify measures to eliminate or reduce risks from exposure to noise so that employees’ hearing is protected. The protection chosen should reflect the level of risk.

Once a noise hazard has been identified and the risks assessed – suitable controls must be implemented. While there are many ways to reduce noise in the workplace such as choosing quieter equipment, introducing engineering controls such as silencers, moving the workplace around to position noise further away from workers; noise cannot always be eliminated and this is where hearing protection comes into play.

The level at which employers must provide hearing protection and hearing protection zones is now 85 decibels (daily or weekly average exposure) and the level at which employers must assess the risk to workers’ health and provide them with information and training is now 80 decibels. There is also an exposure limit value of 87 decibels (dB), taking account of any reduction in exposure provided by hearing protection, above which workers must not be exposed.

What are the action levels and limit values?

The Noise Regulations require employers to take specific action at certain action values. These relate to:

- the levels of exposure to noise of employees averaged over a working day or week; and

- the maximum noise (peak sound pressure) to which employees are exposed in a working day.

The values are:

| Lower exposure action values (daily or weekly average noise exposure level at which the employer has to provide information and training and make hearing protection available.) | Upper exposure action values

(daily or weekly average noise exposure above which the employer is required to take reasonably practicable measures to reduce noise exposure, such as engineering controls or other technical measures. The use of hearing protection is also mandatory if the noise cannot be controlled by these measures, or while these measures are being planned or carried out.) | Exposure limit values (levels of noise exposure which must not be exceeded) |

| daily or weekly exposure of 80 dB | daily or weekly exposure of 85 dB | daily or weekly exposure of 87 dB |

| peak sound pressure of 135 dB | peak sound pressure of 137 dB. | peak sound pressure of 140 dB. |

The HSE’s flow chart will also help you decide what you need to do.

Making sense of attenuation levels, HML, SNR and Db

When looking at the product information for ear defenders there are many categories to choose from and it can be confusing to know exactly what protection is being offered. Below is a simple list explaining the common information you will see on product specifications for hearing protection:

What is attenuation?

The process of losing noise energy is called attenuation.

What is SNR?

SNR is a Single Number Rating system. The SNR value can be used to compare the level of noise attenuation offered by different hearing protectors. To determine acoustic pressure on your ears, you subtract the SNR value from the average noise level measured. For example:

The noise level measures an average of 99 dB.

You are wearing ear protection with an SNR of 19.

Thus, the acoustic pressure on your ears is on average 99 – 19 = 80 dB.

The higher the SNR, the higher the level of noise attenuation provided by the hearing protection.

What is HML?

A method of estimating the attenuation of hearing protection based on 3 parameters.

H = High

M = Medium

L = Low

The terms refer to the noise reduction of the chosen hearing protector at High, Medium and Low frequencies.

What are dBs (decibels)?

dB (decibel) is used to measure the sound intensity. Because the human ear can register sounds across a huge range of intensities a linear scale is not suitable for measurement. The dB scale is therefore a log scale which in very simple terms means the sound intensity roughly doubles for every 3 dB increase. An increase of 20 dB would increase the sound intensity 100 times, (ie 60 dB is 100 times louder than 40 dB)

Note – To calculate the type of hearing protection needed in your workplace, see the HSE’s noise exposure and hearing protection calculators.

Selecting ear plugs for your workforce

Every person’s ear canal is individual to them, as must be their hearing protection. It is essential to get the right fit, the right protection, and ensure the user understands how to use and maintain their ear plugs.

- Selecting ear plugs for the particular noise hazard

Consider the frequency, pitch and intensity of the noise hazard. In industries such as mining workers can be exposed to very low frequencies.

- Selecting ear plugs for your industry

Music, construction and airport workers are exposed to different noise and therefore have very different requirements. Within food and drink factories ear plugs are bright so that they can be easily found if accidentally dropped. There are many ear plugs specially designed for musicians so that the full range of frequencies can be heard and there are specialist hearing protectors for use during firearms practice.

- Selecting ear plugs based on your risk assessment

Your risk assessment should look at the task, the user, the environment, the exposure action values and limit values. The assessment should also identify what you need to do to comply with the law and identify any employees who need to be provided with health surveillance.

- Making sure you meet requirements, standards, certification and legislation

As with any personal protective equipment that you procure, ear plugs should meet the requirements of international standards and relevant legislation. CE markings, EN, ISO and BS codes show which equipment meets standards for safety, design and performance. See the legislation and standards section of this guide to understand more about the exact standards and markings you should be looking for.

Also consider decibels, Single Noise Ratings and frequencies as detailed above.

Remember some in ear monitors and headphones will not meet the criteria of ear protection.

- Choosing the best supplier and manufacturer

Many manufactures now make PPE and ear protection and they can be bought from hundreds of suppliers. If you do not have a preferred supplier for ear protection seek advice from your peers, read independent reviews or seek advice from a networking group. See ‘How to evaluate suppliers / manufacturers below’.

Form a user group and ask suppliers to send some trial samples. Listen to feedback from workers as it is important to have them on board with the PPE they will be wearing.

- Cost and quality – getting the right balance

As with all procurement, selecting PPE can be difficult from a cost vs quality point of view. Foam ear plugs can start at less than £1.00 but may only offer you protection in low hazard environments. Personal custom made ear plugs can offer far greater protection but may set you back in excess of £100. It is a matter of your risk level and selecting appropriate equipment. The higher the noise risk the higher the quality of protection needed. This in turn may lead to a higher price.

Ear plugs can be uncomfortable when first used and if used incorrectly. It is essential that users are instructed on the correct use and insertion of ear plugs and that their ear plugs fit correctly. Products will come with clear instructions on the correct fitting methods to be used.

- Peer reviews and recommendations

Peer review and recommendations are the best way to source impartial, independent feedback on products from people you trust. While reviews online can be helpful, it is always worth starting a discussion within a trusted network first.

How to evaluate suppliers and manufacturers:

When choosing your product, consider:

- Established companies

- Recommendations from within your network

- Does the supplier provide equipment with the correct markings that meet Standards?

- Are they certified?

- Do products come with informative leaflets showing how to use the PPE safely?

- Are the products covered by a warranty?

- Is the supplier part of the Registered Safety Supplier (RSS) Scheme?

- Restrictions and warnings for use and wear on the supplier’s products

Does one size really fit all? Meeting the needs of your diverse workforce

When buying, using and maintaining ear plugs within your workplace, remember:

- The ear and ear canal varies from person to person – ensuring the correct fit is a must for making sure the ear plug is actually offering protection.

- Existing medical problems affecting the ears.

- The benefits of testing different brands.

- There are laboratory custom made ear plugs and DIY custom made ear plugs. Depending on your task and risk level one may be more suitable than the other.

- It may take time for the workforce to adjust to wearing ear plugs, or wearing new ear plugs

- As with all PPE ear plugs must be maintained and kept clean. If they are broken it must be reported to a manager and the situation rectified before the worker returns to the hazardous environment.

Types of ear plug

- Disposable single use ear plug – Disposable foam ear plugs are made from expandable slow-recovery foam. They are squeezed or rolled into shaped and then inserted into the ear canal where they gently expand causing a seal to protect against noise. There are ‘no roll’ ear plugs which do not require squeezing into shape before use and corded foam ear plugs which are attached by a cord which is helpful if you have a job where you are taking your ear plugs out a lot.

- Advantages: Inexpensive and simple to use. Effectively protect against high sound levels. Smaller than earmuffs – can be carried in a pocket. More comfortable than earmuffs in hot environments.

- Disadvantages: Can provide uneven frequency attenuation – remove more high frequencies than low. Require careful insertion to ensure effective protection. Risk of infection from dirty hands.

- Banded ear plugs, canal caps or pods – Are essentially ear plugs mounted on a headband. They are good in environments where ear plus need to be removed frequently or where the environment is too hot.

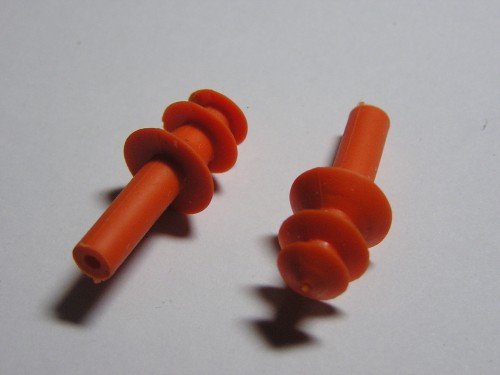

- Reusable multi-use pre-moulded ear plugs – These ear plugs reduce waste in comparison with disposable ear plugs as they can be cleaned and re-used. They generally have flanges which are flexible ridges or flaps that circle around the middle of the plug. Flanges help a reusable ear plug seal against your ear canal.

- Advantages: Less expensive than custom-moulded earplugs. Easy to insert properly. Last longer than compressible earplugs. Do not require custom-fitting – available off-the-shelf. Reusable – if kept clean.

- Disadvantages: More expensive than compressible earplugs. Uniform attenuation types generally not as ‘flat’ as custom-moulded uniform attenuation earplugs.

- Custom made ear plugs (lab made / make your own) – Custom moulded ear plugs can either be made by a company on your behalf, who will take casts of your worker’s ears and create individual ear plugs; or there are DIY kits for you to create your own custom made plugs.

- Task specific – there are many sorts of ear plugs for specific tasks such as shooting, metal detecting and for musicians.

- Ear plugs for protection from water – people who spend a lot of time in water need to protect their ears, and can use ear plugs which let sounds in but keep water out. These ear plugs can prevent “swimmer’s ear”, and ear pain by blocking water from entering the ears.

- Ear plug accessories – replacement tips, cases and other accessories are available to help ensure you keep your ear plugs clean and safe.

- Ear defenders/ ear muffs – See more information about ear defenders in our ear defenders buyer’s guide.

Hygiene in hearing protection

To make sure ear protection is kept to the best standards:

- Ensure you buy good quality ear plugs

- Keep ear plugs clean according to their instructions. Re-useable ear plugs often just need cleaning with soap and water after each use, especially around the flanges.

- Know when it’s time to buy new ear plugs – reusable ear plugs will not last forever. Depending on how often they are used it may be weeks or even months before you need a new pair. If they are cleaned and stored correctly they will last longer. If ear plugs are broken, torn, discoloured or stiff it will be time to replace them.

- Correct insertion is essential for the safe and hygienic use of ear plugs. Follow manufacturer’s instructions for how to use, store and maintain ear plugs.

Legislation, standards, ratings and markings

Legislation

The Control of Noise at Work Regulations 2005 replace the Noise at Work Regulations 1989 and aim to ensure that workers’ hearing is protected from excessive noise at their place of work, which could cause them to lose their hearing and/or to suffer from tinnitus (permanent ringing in the ears).

The updated regulations introduce new requirements for action to be taken by employers. For example, the 2005 Regulations require employers to take action to protect workers at levels of noise 5 decibels lower than in the 1989 Regulations and now require health surveillance (hearing checks) for workers regularly exposed above 85 decibels.

Other legislation to be aware of when it comes to noise at work, includes:

There are other regulations for:

Standards

A list of titles and references harmonised standards under Directive 89/686/EEC for Personal protective equipment (PPE) is available. See below for standards relevant to hearing protection.

| CEN | EN 352-1:2002 – Hearing protectors – General requirements – Part 1: Ear-Muffs |

| CEN | EN 352-2:2002 – Hearing protectors – General requirements – Part 2: Ear-plugs |

| CEN | EN 352-3:2002 – Hearing protectors – General requirements – Part 3: Ear-muffs attached to an industrial safety helmet |

| CEN | EN 352-4:2001 – Hearing protectors – Safety requirements and testing – Part 4: Level-dependent ear-muffsEN 352-4:2001/A1:2005 |

|

| CEN | EN 352-5:2002 – Hearing protectors – Safety requirements and testing – Part 5: Active noise reduction ear-muffsEN 352-5:2002/A1:2005 |

|

| CEN | EN 352-6:2002 – Hearing protectors – Safety requirements and testing – Part 6: Ear-muffs with electrical audio input |

| CEN | EN 352-7:2002 – Hearing protectors – Safety requirements and testing – Part 7: Level-dependent ear-plugs |

| CEN | EN 352-8:2008 – Hearing protectors – Safety requirements and testing – Part 8: Entertainment audio ear-muffs |

| CEN | EN 458:2004 – Hearing protectors – Recommendations for selection, use, care and maintenance – Guidance document |

| CEN | EN ISO 4869-2:1995 – Acoustics – Hearing protectors – Part 2: Estimation of effective A-weighted sound pressure levels when hearing protectors are worn (ISO 4869-2:1994)EN ISO 4869-2:1995/AC:2007 |

| CEN | EN ISO 4869-3:2007 – Acoustics – Hearing protectors – Part 3: Measurement of insertion loss of ear-muff type protectors using an acoustic test fixture (ISO 4869-3:2007) |

There are many noise emission standards, some for specific classes of equipment such as EN 60745 series, noise emission of portable powered hand tools, and others such as BS EN ISO 4871:2009, the declaration and verification of noise emission values of machinery and equipment with more general application. Standards are available from The British Standards Institution (BSI)

USA – Noise Reduction Rating (NRR) is a unit of measurement used to determine the effectiveness of hearing protection devices.

CE Markings

After 30 June 1995, all PPE placed on the market in EU Member States was required to comply with the requirements of Directive 89/686/EEC and carry the CE Marking

Conclusion

As with all PPE there are many things to consider when selecting a product for you workforce. Below is a summary of the key things to consider when buying ear plugs:

- Make sure you effectively control the risk, taking into account the task and the environment. Consider the correct level of attenuation, the level, frequency and pitch of the noise hazard.

- Do not over-protect. Cutting out too much noise can cause isolation, or lead to an unwillingness to wear the protectors. Ensure workers can safely hear alarms and that they can still communicate effectively.

- Ensure that ear plugs are comfortable and suitable for the working environment. Remember everyone will find different things more or less comfortable than the next person. Consider how comfortable and hygienic the protectors are, whether they will be worn with any other protective equipment, and how the activity of the user can be accommodated.

- Ensure your workers understand how to use their PPE correctly.

- Ensure workers wear ear defenders at the right time – whenever there is a noise hazard present. Workers need to be told when and where to wear hearing protection.

- PPE is readily available to all who need it and actively supplied by the employer.

- Ear protection is properly maintained, in good, clean and undamaged condition.

Further information:

http://www.hse.gov.uk/noise/regulations.htm

http://www.hse.gov.uk/noise/risks.htm

http://www.hse.gov.uk/noise/calculator.htm

http://www.hse.gov.uk/pubns/indg363.htm

http://www.hse.gov.uk/pubns/indg362.htm

http://www.hse.gov.uk/pubns/books/l108.htm http://www.magidglove.com/guide_hearing%20protection.aspx

http://www.consumersearch.com/earplugs/how-to-buy-earplugs

http://www.protectear.com/custom-plugs-vs-disposables/

http://www.earplugs.co.uk/Industrial/c-1-421/

http://www.hse.gov.uk/noise/buy-quiet/index.htm

http://www.hse.gov.uk/noise/hearingprotection.htm

https://www.tuc.org.uk/sites/default/files/extras/noiseatwork.pdf

http://scholar.lib.vt.edu/theses/available/etd-04192011-143941/unrestricted/Lee_K_D_2011.pdf

http://ec.europa.eu/growth/single-market/european-standards/harmonised-standards/personal-protective-equipment/index_en.htm

http://www.industrialworkwear.com/upload/Hearing-Protection-markings.pdf

www.tuc.org.uk/noise

http://www.rnid.org.uk

http://www.tinnitus.org.uk

Ear plugs at work – a buyer’s guide

What are ear plugs? Ear plugs are generally used in the workplace to help protect the user’s ears from excessive

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

ESG consultants key spend for sector, survey reveals

SHP’s Annual Products and Services Report – 2023

Sustainable packaging: Is your business supporting the circular economy in the fight against single use plastics?

Once a noise hazard has been identified and the risks assessed – suitable controls must be implemented. While there are many ways to reduce noise in the workplace such as choosing quieter equipment, introducing engineering controls such as silencers, moving the workplace around to position noise further away from workers; noise cannot always be eliminated and this is where hearing protection comes into play.