Events such as the Grenfell Tower disaster have had a profound impact on the way the construction industry reviews its building standards. Matt Ryan, UK Country Manager at PlanRadar, explains how digital tools are providing the next step in fire safety inspection and compliance.

The revelations uncovered by the ongoing Grenfell Inquiry show that, worryingly, UK housing is still falling short of the mark when it comes to fire safety protocols. Recently, the London Fire Commissioner called for urgent action after the number of apartment blocks in London deemed unsafe exceeded 1,000. Other incidents, including an East London housing association asking residents to leave a tower block due to ‘an immediate’ fire risk, only hint at the scale of the issue.

A number of players, from resident’s associations to fire engineers, have repeatedly highlighted the persistent, considerable risk to life. It is clear that fire safety within residential buildings needs to drastically improve to mitigate risk and protect occupants, particularly those in high-rise flats.

The good news is that more attention is now being dedicated to this issue and significant progress is being made. While the industry already contains the necessary experts, they are leading an agenda that brings new strategies to overcome this problem. The recent increase in digital adoption by the construction sector is at the heart of these improvements.

Building a safer future

Back in May 2018, Dame Judith Hackitt’s review of building regulations and fire safety was released. Commissioned in response to Grenfell, the report revealed a need for greater fail-safes and a requirement for what she called ‘The Golden Thread’ of information. Relating to all structures, this framework aspires to provide an accurate timeline of a building (a digital blueprint that allows for easy-to-access, detailed recording keeping).

Since then, the government has proposed further laws to promote better working practice. The introduction of a new building safety regulator and new construction product regulator represents a landmark step, implementing a new, more rigorous framework for higher-risk buildings to ensure the safety and performance of a buildings meets legal requirements.

Legislation with ‘bite’

The new legislation has bite, with serious financial and legal ramifications for those who choose to ignore it. In Hackitt’s words, “It will not look to see you have merely followed the rules, but check the building is safe, from planning to occupation and you’ve done everything in your power to ensure this.”

Contractors and designers will have to legally demonstrate a building is safe, requiring regulator sign-off before projects can move forward. Whilst this may seem a daunting prospect, emerging tech and digital tools are streamlining this process.

Finally, the industry is waking up to the power of digital and its ability to improve inspections, compliance and record keeping, reducing the likelihood of mistakes and raising standards across the board.

Digital construction: Leading the way

The construction sector often hinges profitability on projects being completed within a specific timeframe.

The construction sector often hinges profitability on projects being completed within a specific timeframe.

However, this rush to meet deadlines means building safety protocols can slip, with team members completing tasks simply as part of a box ticking exercise rather than with due care and attention. While this increases risk for the end user of a building, it also adds ambiguity in the event of an accident.

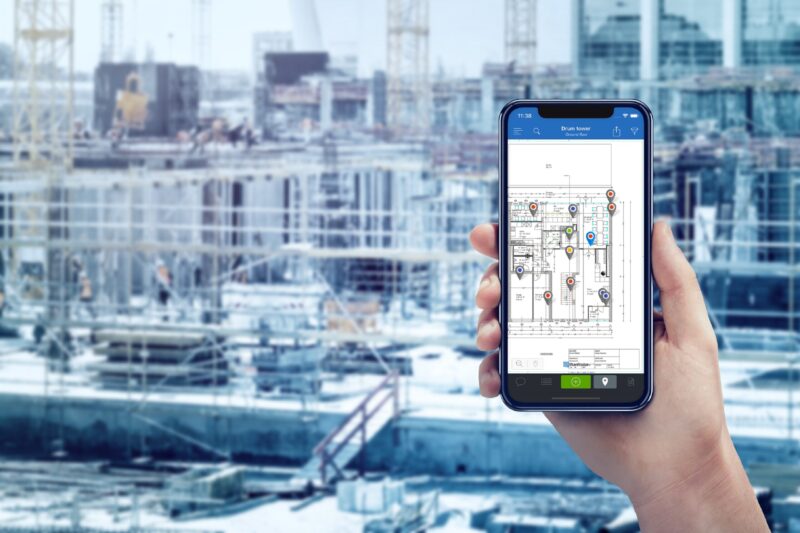

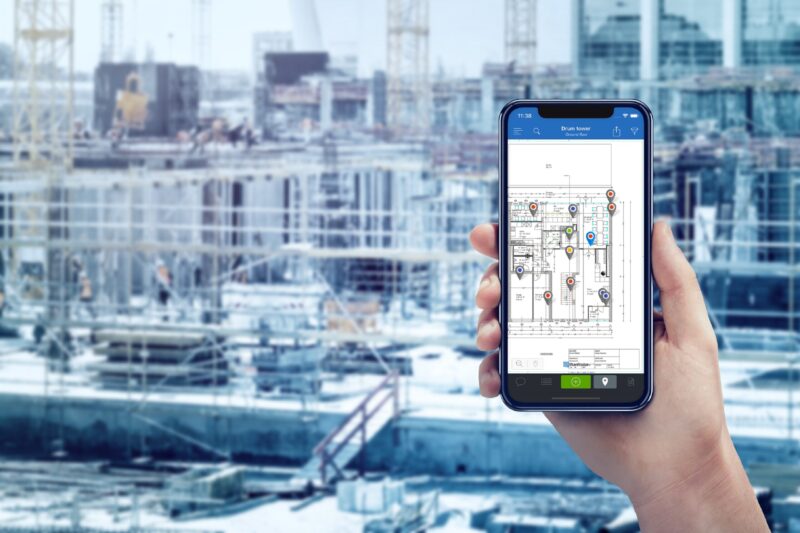

Which contractor or subcontractor is responsible for a mistake is often unclear in the paper trail. Yet, on-site workers are now being given access to digital devices that can prove work has been carried out to the correct standard.

Platforms and apps that allow workers to use technology they are already familiar with, be it a phone or tablet, are being taken up with gusto. As a result, anyone on site can capture evidence of their completed work, automatically creating a tamperproof audit trail with date and timestamps. With the power to document successful installations and maintenance comes the ability for all project participants, from large contractors to individual tradespeople, to assert responsibility: I did this right, at this time, and I can prove it.

Additionally, this technology enables safety experts to upload and complete digital replicas of safety inspection sheets. This allows for more accurate and time efficient record keeping and does away with the laborious task of entering handwritten notes into word processing or spreadsheet programmes, which run the risk of human error during the transfer, making audit trails unreliable. What’s more, it removes the need for outdated ways of storing important paperwork and documentation, which can easily become lost or misplaced.

QSHE Managers can even update these inspection sheets from the office, rolling out new fields for site teams to complete seamlessly across multiple sites at once. When new guidance is published, it’s possible to start the journey towards compliance the very next day.

Cloud-based technology allows documentation to be stored securely while being available to those with the right permissions, wherever they are. As remote working is now a part of daily work routines, project managers also have the added advantage of receiving up-the-minute safety inspection information whilst being off-site. Managers overseeing multiple sites at once also benefit from this instant visibility.

Harnessing ‘unstructured’ data

As the role of ‘big data’ is becoming increasingly important to companies looking to gain deeper insights into business performance, in-app tools are helping to realise its potential, collecting ‘unstructured data’. This is valuable information that isn’t as neatly packaged as spreadsheets and numbers but encompasses other areas, such as emails and text messages.

With the ability to send-in app photo and video documentation, companies can ensure a record of ‘unstructured data’ is still being logged, for later review by AI and data analysis experts. From a health and safety perspective, being able to share this type of information between teams can be extremely beneficial, ensuring checks are watertight.

What’s more, this greater level of communication improves overall cohesiveness with those working on projects, helping to leave no stone unturned when it comes to safety compliance.

Peace of mind

With such a wide scope of what can be achieved when adopting digital methods, it’s no surprise that more companies are now refreshing their digital strategies to improve quality control.

Beyond this, these tools represent something that money can’t buy: peace of mind. As individuals will now be at risk of being held personally accountable should failures occur, those in charge can feel comfortable relevant safety checks have been made, with the knowledge of a digital record to prove it.

If we’re to fulfil the Government’s dream of ‘Building Back Better’, then it starts by using all the tools at our disposal. Above all, ‘by choosing digital’ the sector can take a step closer to Hackitt’s vision of achieving the ‘Golden Thread’ and once again look to rebuild its reputation as sector that puts safety first, regardless of cost.

To read the Hackett review in full, click here.

Lessons from Grenfell: Why aren’t we learning?

In this episode of the Safety & Health Podcast, we hear from Gill Kernick about the pressing need to improve building safety culture post-Grenfell.

The Safety Conversation Podcast: Listen now!

The Safety Conversation with SHP (previously the Safety and Health Podcast) aims to bring you the latest news, insights and legislation updates in the form of interviews, discussions and panel debates from leading figures within the profession.

Find us on Apple Podcasts, Spotify and Google Podcasts, subscribe and join the conversation today!