How interlocked guards often fail, and what you can do to prevent them

Phil Chambers BSc CMIOSH

Interlocked moveable guards give us the reassurance that we are controlling the risks posed by machinery. However, nothing is 100% reliable and so guard interlocks and trips need to be checked regularly. This describes some common failure modes of such devices.

Failure 1 — Deliberately overridden

In the working environment, there is sometimes the temptation to speeds things up, or to overcome problems, by overriding the switches. Typically, this is done by removing the retaining screws from the tongue and inserting it into the switch. Alternatively, a second tongue could be inserted into the switch.

Methods of overcoming this are:

· Stress to employees that they are breaking Section 8 or HSAW, which is effectively a criminal act and the company would take disciplinary action against whoever did it. (The only snag is that it is difficult to prove who actually did it.)

· Fit tamper-proof screws and have a plate with 2 tapped holes instead of 2 nuts. That way, nobody can put pliers or a spanner on the nuts.

· Use coded switch/tongue pairs, which will only work together. That way a duplicate tongue will not work.

Failure 2 — Broken interlock

This photo shows two interlock switches that inspire no confidence at all. Such switches are not expensive and should a switch get in this state, then you must replace it.

Failure 3 — Unreliable interlock

This next picture shows a switch activated by a cam on the pivot. Normally, this is a reliable arrangement, but in this case the whole guard can move from side to side, and when moved to the far left, the cam disengages with the switch. A couple of washers on the pivot to remove the sideways movement would prevent this.

Failure 4 — Jammed trip

This is not as obvious as the first three failure modes. Say you have a trip on an in-running nip where if an object (like your finger) is drawn into the nip, the equipment stops. (Such devices are common on machines like litho presses where manual cleaning can be done safely on slow crawl providing you have such a trip.) If the trip actuator is jammed, then it cannot move and activate the switch. One example where this became apparent during a test was on a press where the actuators were jammed with solid ink. The way to overcome this is to carry out regular tests, say by poking the actuator with a stick and verifying that it works.

Failure 5 — No trip

You could argue that this is not really a failure, but in some operations it is desirable to have an out-of-range alarm which trips if an excessive level is reached. One example was a company which had hot melt gluers, but there was no over-temperature trip on the glue baths. On one tank, the heater stuck on and the resultant fire caused damage running into the millions and the eventual sale of the company. All for a switch which can be bought for £20.

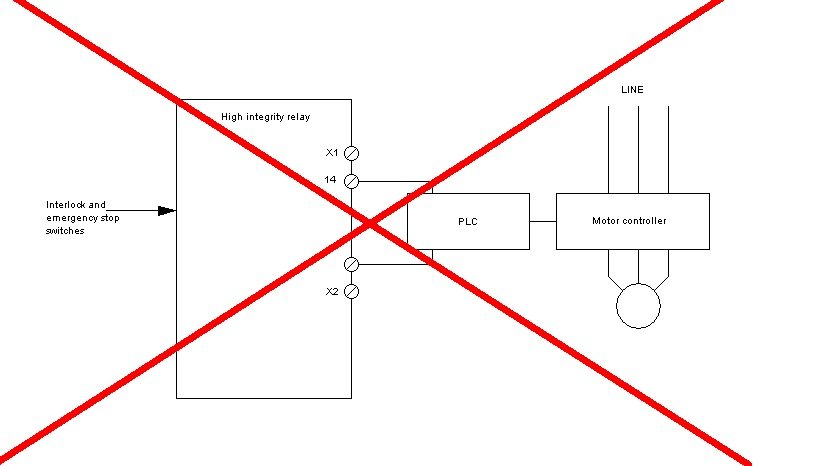

Failure 6 — Poor siting of high reliability devices

You can achieve high reliability by using specialised interlock switches with dual channels, feeding into a positively guided relay with cross-checking. This is a super arrangement but I have often seen this compromised by feeding the relay output only into a PLC. This is not necessarily a problem but you introduce a whole raft of verifications of the PLC and its program that some people never consider.

The solution is simple: Use the relay output to control the power outputs, feeding the state of these back to the relay for added reliability.

Failure 7 — Fault masking

In complex guard arrangements, it is common, for economic reasons, to have dual channel switches wired in series. However, it is possible for 2 faults to combine to mask themselves. Solutions by interlock device manufacturers include intelligent switches. Rather than attempt to cover this complex topic in this article, I suggest that you refer to other publications such as this one by Pilz http://bit.ly/1p2vXTw (other manufacturers provide similar information.)

All the above show examples where interlocks can fail. So the lessons are:

-

Do not assume that they will always work reliably.

-

Ensure that their design is reliable.

-

Carry out checks at an appropriate frequency.

Approaches to managing the risks associated Musculoskeletal disorders

In this episode of the Safety & Health Podcast, we hear from Matt Birtles, Principal Ergonomics Consultant at HSE’s Science and Research Centre, about the different approaches to managing the risks associated with Musculoskeletal disorders.

Matt, an ergonomics and human factors expert, shares his thoughts on why MSDs are important, the various prevalent rates across the UK, what you can do within your own organisation and the Risk Management process surrounding MSD’s.