CDM in the industrial and manufacturing environment

As we all know from the Construction (Design and Management) Regulations 2015 (CDM 2015), construction work means the carrying out of any building, civil engineering or ‘engineering construction work’. Clearly this is wide scope and will encompass work carried out in many industrial, technology and manufacturing sectors. This article discusses how CDM 2015 can be applied, and how Turner & Townsend can assist clients in this area.

The applicability of the Construction (Design and Management) Regulations within technology and manufacturing industrial environments, is often not discussed and the meaning of engineering construction work is not easily understood.

The Engineering Construction Industry Association (ECIA) has attempted to define engineering construction work as the ‘design, construction and maintenance of process plant across the oil and gas, water, environmental, steel and metal, cement, glass, paper, brewing and distillation, food, power generation, nuclear waste reprocessing, pharmaceutical production, petrochemical and chemical sectors.’

The following industrial and manufacturing related activities may well place an organisations projects into the scope of CDM 2015:

- Design and installation of new machinery;

- Re-organising or redesigning machinery, processes or physical layouts within a facility;

- Dismantling machinery or processes for repair, refurbishment or decommissioning;

- Building an extension to, or demolishing part of a facility;

- Modifying internal facility areas by installing (or removing) structures such as walls, adding levels or elevated walkways; and

- Installation, commissioning, maintenance, repair or removal of most mechanical, electrical, gas, compressed air, hydraulic, telecommunications, computer services if part of construction work.

However, as the CDM 2015 regulations continue to use the word ‘construction’ in an open way it can cause clients to mis-understand their duties, and leave them facing potential legal action for non-compliance. This is especially important in today’s climate of enhanced criminal enforcement under the recently issued Sentencing Guidelines for Health and Safety and Corporate Manslaughter offences.

In the past, under the previous regulations, CDM co-ordinators (CDMC’s) often concentrated on traditional construction work, and also tended to provide an information flow and co-ordination activity, rather than focussing on the co-ordination of engineering design efforts – leaving that to engineers and project managers. This was especially true in the technology and manufacturing sector – often due to lack of technical competence of CDMC’s in this area which, if left unresolved, left an ominous gap no-one would potentially fill.

CDM 2015 implications

What many clients often miss within CDM 2015 is that the roles of designers and principal designers are also required for engineering construction work including the design of equipment and processes. There is now a clear requirement for a principal designer to co-ordinate all design activities on behalf of clients.

Also, under CDM 2015, the client has the duty to appoint a competent and resourced principal designer. This is not triggered by any notification thresholds, so even if the project is short duration, but with multiple designers, clients will have a duty to appoint a principal designer.

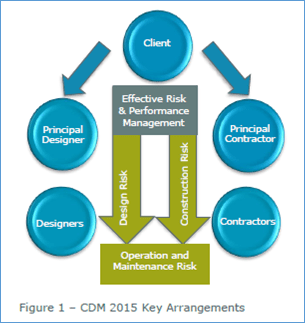

Figure 1 – CDM 2015 Key Arrangements

As can be seen from figure 1, the principal designer is now a key role within CDM 2015. This is not simply a replacement for the previous CDMC duty holder, and where necessary they are expected to have the skills, experience & knowledge (competence) to fill the aforementioned gap, and provide a true co-ordination of technical design competencies for engineering construction work.

To assist clients, it would be helpful if individuals or organisations intending to operate as principal designers had a portfolio of information available to demonstrate their competence – both technical and construction. Remember, CDM 2015 places duties which need to be carried out prior to commencement of the work on site, so planning ahead is essential for clients to ensure engineering construction work in technology and manufacturing activities comply.

What Does This Mean for Industrial and Manufacturing Organisations?

Within the technology and manufacturing sectors machinery and process improvement projects often include significant design challenges / modifications and installation of equipment for a wide variety of uses. As part of this, the principal designer will be responsible for advising the client and collating the required pre-construction information (PCI), on some potentially highly technical engineering design and safety issues. They will need to ensure that arrangements are in place for pre-construction information co-ordination and the management of health, safety and environmental risks during the design process. Information on these risks then needs to be transmitted effectively to the principal contractor.

For high hazard and complex systems, risk analysis techniques are practiced to achieve safety through inherent design, and attempts made to reduce risks to a level of ‘as low as is reasonably practicable’ (ALARP). Process designers are familiar with using a variety of risk assessment and hazard study techniques to design out and reduce risks to the lowest practicable level. Such techniques can include studies such as; Hazard and Operability (HAZOP), Failure Modes Effect Analysis (FMEA), Layers of Protection Analysis (LOPA) etc.

Taking one of these, when most people think of a HAZOP, they are thinking of a design HAZOP which is carried out to verify and determine residual risks in the detailed phase of process equipment. In fact the HAZOP process starts before this, ideally at the feasibility stage, and indeed continues into procurement, construction, commissioning and operation. This will often involve monitoring the design information and intent, to ensure that all risk controls identified as part of the HAZOP are either already designed in, or required as part of the residual risk management strategy.

One issue that often arises when undertaking hazard studies (such as HAZOP’s) is that clients often specify a time limit for the studies, as they can tend to become open-ended if not carefully managed. However, a further duty of the client under CDM 2015 is to ensure that sufficient time is allowed for the design to take place – including hazard studies. Therefore a conflict can arise between compression of project timescales, for both time and cost purposes, and satisfying their legal duties under CDM 2015. Again, an effective principal designer would be well placed to highlight this, and challenge the client on this issue should conflicts on timescales arise.

There are many areas where the principal designer will potentially have an input into the project process, as designs could change (such as when the equipment is installed and commissioned into service) and certainly in the compilation of the health and safety file.

Many large scale industrial projects will inevitably involve procurement of equipment from non-UK designers and equipment suppliers. In these cases the designers may not fall under the requirements of the European directive for Temporary of Mobile Construction Sites, and therefore there may be little or no understanding in the requirements of CDM 2015 or the principal designer role. As such clients should be aware of this and ensure that the principal designer appointed has the necessary gravitas and authority to ensure that all design risks are assessed, mitigated and known for the future operations phase.

As previously discussed, individuals and organisations cannot accept an appointment under CDM 2015 unless they are competent and adequately resourced to do so. Therefore individuals and organisations offering the principal designer role must have effective governance and procedures in place to assure the client they can deliver the duties of the role. As with all duty holders, the right skills, experience and knowledge are fundamental to compliance i.e. competence and assurance are the keys to success.

Beyond Design

Many client organisations hand over the installation of equipment, once purchased or designed, to a specialist installation contractor. However, clients often make the mistake of using internal teams to procure these services, who often lack the specialist skills needed to understand the effects of their decisions on the project risks, schedule, programme etc.

To ensure that all hazards, and subsequent mitigations addressed in the design phase are implemented, it is important to ensure that equipment layout, and operator / maintenance interfaces are constructed and installed as designed. The client will often be familiar with the concept of working with a principal contractor, but also has a duty to ensure the principal contractor is adhering to all the health and safety design principles through installation.

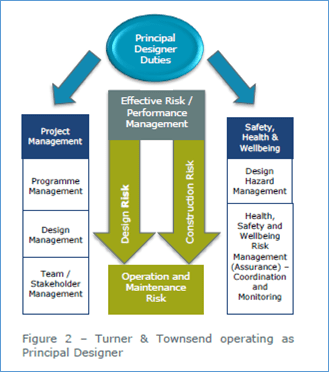

Figure 2 – Turner & Townsend operating as Principal Designer

We have the necessary skills and competence to assist clients and principal designers working in high hazard industries to ensure that all engineering construction work is carried out in accordance with CDM 2015, help duty holders to remain within legal compliance and provide best practice input into a client’s project. Turner and Townsend can bring together these skill across a variety of industries such as:

- FMCG manufacturing;

- Automotive and assembly;

- High hazard process industries;

- Leading edge technology industries such as aerospace, telecoms etc;

- Utility providers such as; water, oil and gas. For further information on any of our services visit our website© Turner & Townsend Project Management Limited. This content is for general information purposes only and does not purport to constitute professional advice. We do not make any representation or give any warranty, express or implied, and shall not be liable for any losses or damages whatsoever, arising from reliance on information contained in this document.

- It must not be made available or copied or otherwise quoted or referred to in whole or in part in any way, including orally, to any other party without our express written permission and we accept no liability of whatsoever nature for any use by any other party.

- With a unique blend of technically competent engineering construction design, installation and management professionals, Turner & Townsend should be your first call for industrial and manufacturing CDM support.

Where Turner & Townsend can help

With a wealth of experience in project management, the construction industry and the transition and implementation of CDM 2015, Turner & Townsend are in an excellent position to also support industrial and manufacturing clients and principal designers, by guiding and supporting them through the delivery of their duties under CDM 2015.

Design HAZOP’s and CDM

Turner & Townsend have experience of performing varied principal designer duties, bringing together both traditional construction design and also technical design activities, such as HAZOP’s, under CDM 2015.

In such roles we not only co-ordinate the design teams, but also the various hazard study teams, presenting the client with a technical solution as the principal designer.

As part of our health, safety and wellbeing team we have the capability to handle most types of engineering construction activities which fall under CDM 2015.

Continuing CDM into Installation

Turner & Townsend have co-ordinated health and safety of the build and fit out of major industrial installations, working within the client’s project team including their Project /Construction Managers who programmed and scheduled the works.

As such, we can manage the whole project life cycle from ground works to final test production. During installation and fit out, projects are often interpreted by clients as falling outside the traditional definition of construction.

Our approach is to act as a principal contractor through our safety and support services management team, interfacing (on behalf of the client) to the following teams; project management, scheduling and programming, and the design and installation teams.

For further information on any of our services visit our website: www.turnerandtownsend.com

CDM in the industrial and manufacturing environment

As we all know from the Construction (Design and Management) Regulations 2015 (CDM 2015), construction work means the carrying out

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Almost half of UK manufacturing employers have increased spending on workforce health and wellbeing

New cladding fire risk identified and could be “tip of iceberg”

Bedding manufacturer fined after employees suffer serious injuries

Good article,

As a comment where the design is undertaken outside the UK the Principal Designer will (in most cases) have the support of the client who under reg 10 is responsible for ensuring the designers compliance / engagement?

Great