Safety performance: Making waves

By Richard Byrne BSc (Hons), CMIOSH, PIEMA

Normally when you talk about making waves it is seen as something with negative connotations; changing things which will upset others, causing controversy or a disturbance. At times we all make waves. There are examples in the world of health and safety when making waves – in performance terms – is good and not so good and, by the very nature of what I’m about to say I might be making waves, so here goes.

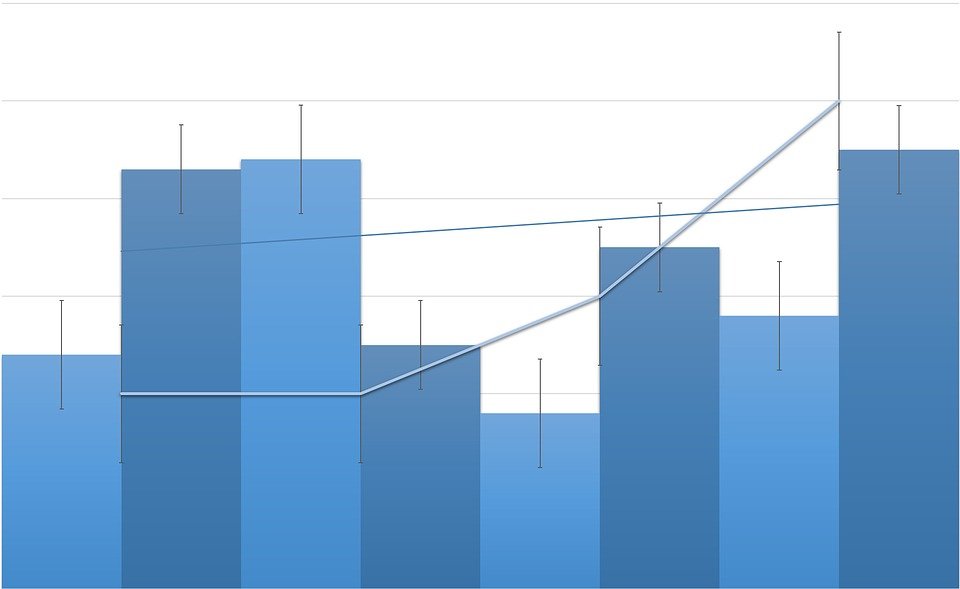

When you look at an organisation’s safety performance, how often do you see a wave effect – for example an increase in the accident frequency rate for one year – only to see it fall the next year and rise again the year after? In truth, I reckon, quite a lot.

What does this sort of wave effect mean? Simply put it means that the overall approach, or strategy, towards health and safety management and improvement of the organisation, business unit or site (whatever you are looking at) is too short term.

Let’s unpack that a little more.

Imagine your accident frequency rate over the previous few years steadily increases to a point where the change is really quite noticeable. You do some digging and realise that it is to do with people hurting their backs when handling products. You decide the best way forward is to introduce or re-engerise manual handling training (you know the stuff: “back straight, bend your knees, show me how to do it with that empty box” style of training) and you even manage an objective for managers to make sure their teams do the training. When you look at the accident frequency rate next year, chances are you will see the accident frequency rate start to come back down – at least for that cause.

The next year, thinking you’ve cracked it, you move on to focus on another topic only to find that manual handling events start to make a comeback. The reason you are getting a wave in your performance is because you haven’t made a sustainable change in the culture of the organisation in relation to managing the risk of manual handling.

To avoid this situation the thing to do would have been to continue your programme to focus on preventing handling injuries into years two and three – only at that point are you likely to see a real lasting improvement.

Not only that but you should deal with the cause of the problem and not just the symptom – in this case why are people lifting in the first place? Can things be changed in their work area so that less lifting is done or rearranged such that better handling techniques can be used more readily?

There are two real tricks to use here:

- make sure you pick the biggest area that is affecting your accident experience and risk profile; and,

- develop a strategy to deal with it. Not a plan – anyone can write a ‘what, how, who, when’ tactical plan. A strategy thinks about what you are going to do over the longer term and is something we often overlook in the safety profession, as we are too focused on the here and now.

Unashamed plug time (yep here’s me making a wave or two) – my new book has a complete chapter dedicated to forming a safety strategy. No safety qualifications that I’m aware of cover it – and it is the ability to do so that is absolutely fundamental to safety professionals being effective safety leaders. (https://www.routledge.com/World-Class-Health-and-Safety-The-professionals-guide/Byrne/p/book/9781138183902).

So when is making a wave a good thing? The answer is in your near miss data. Imagine this: colleagues report a near miss, this happens across the organisation. You notice this upward trend in reports when you do your trend analysis and realise that the majority of them relate to a specific issue. Hence your trend line is increasing over time.

You turn the near miss data into information for the management team to use e.g. this is the issue, this is what we should do. There is some positive management action as a result and over time, if the action is the right action, you should see the number of near misses start to fall.

And so begins another wave.

Richard Byrne is health and safety director for the contract merchanting division of Travis Perkins

Safety performance: Making waves

By Richard Byrne BSc (Hons), CMIOSH, PIEMA Normally when you talk about making waves it is seen as something

Safety & Health Practitioner

SHP - Health and Safety News, Legislation, PPE, CPD and Resources Related Topics

Navigating turbulence: Boeing’s lessons in risk management

Verdantix Green Quadrant: EHS Software 2023

Creating and Sustaining a Safety Culture: A mini-guide for today’s health and safety pros